Ben that sounds super cool , I'd love to go down that road but I'm just not in the position this side of Xmas ,and I'm sure the quicker for you the better as I'm sure it would help with your reputation in this application, I won't lead you astray ,as it would be summer before I could take you up on that generous offer,

But I sure will be here in the meantime waiting on your updates,

You seem to have the passion and the know how for what you are doing , which in turn gives customers alot of confidence in yourselfs ,

For that you have my respect and attention.

Kind regards Lee.

No problem Lee, was just an option if you were thinking of going down that route. Let me know if you would be interested at a later date, I'm not going anywhere far and will always be about on here so just drop me a PM

To be honest Lee I love cars, I love engines, and I love how they work, people take cars for granted as they just buy them use them and eventually abuse them. When you look at the bigger picture and see what has actually been achieved it really is amazing, no one ever thinks of the thought processes that go into creating the engine and chassis as a full package.

And now although I don't really ''own'' a Honda they really are still my favourite cars, they are just a joy to drive and work on, much MUCH better than the S3 and MUCH more reliable than the Evo, I would have another Honda any day! I am looking at Dc2's at the moment as I have never owned one and would be a happy medium as a daily instead of the S3 and also considering selling the Evo and getting either another Ek9 or another Crx as a weekend/track toy.

The.Sho-Dan - Thanks, better to think before following what others tell you to do I think

tico-ek9 - Thanks! nice to see people are enjoying what we are doing.

Anyway back on topic and updates with the D16 build

I was doing a little math earlier to see how much had been spent so far on this build, when I go to £6800 I stopped thinking about it! But this can obviously be done much cheaper as the headwork isn't necessary and there are plenty of cheaper turbos, radiators, intercoolers, oil coolers, ecu's out there.

We have now made progress on the intercooler piping, our original intentions were to move the radiator over towards the manifold about 2 inches so that we would have enough room to get the cold side intercooler pipework through there and directly up to a 90 bend and straight into the throttle body. BUT now that the engine is in and we have the manifold on and because of how deep the Mishimoto Radiator is it would of been impossible to do that. We have decided on the usual route of going around and under the chassis leg, not ideal but it will work, maybe a space framed front end next year to give us more room to do what we originally wanted.....

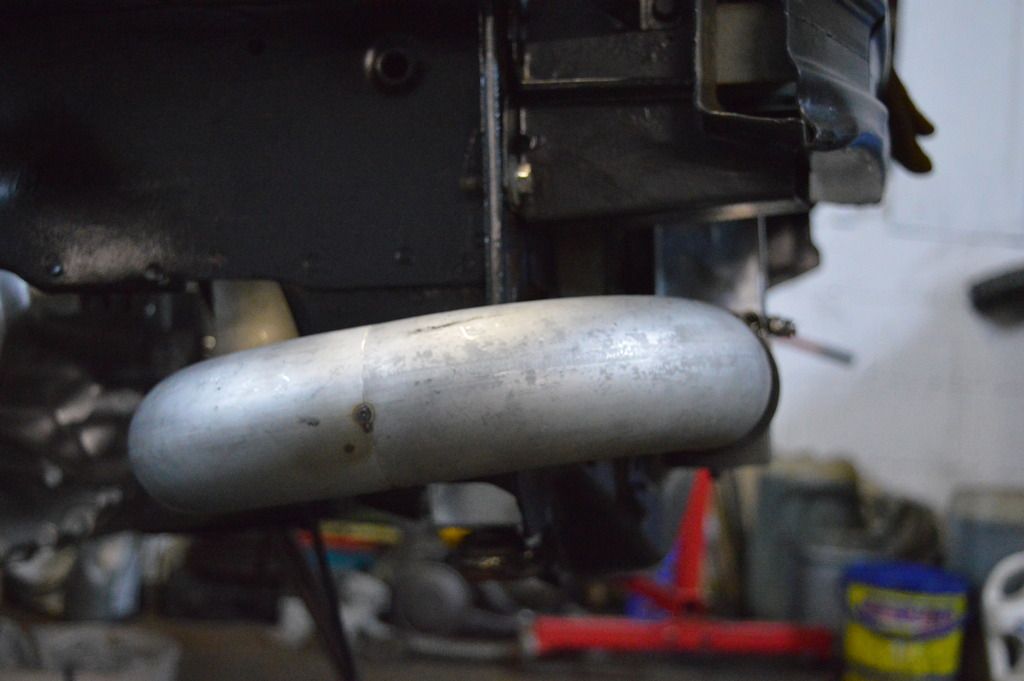

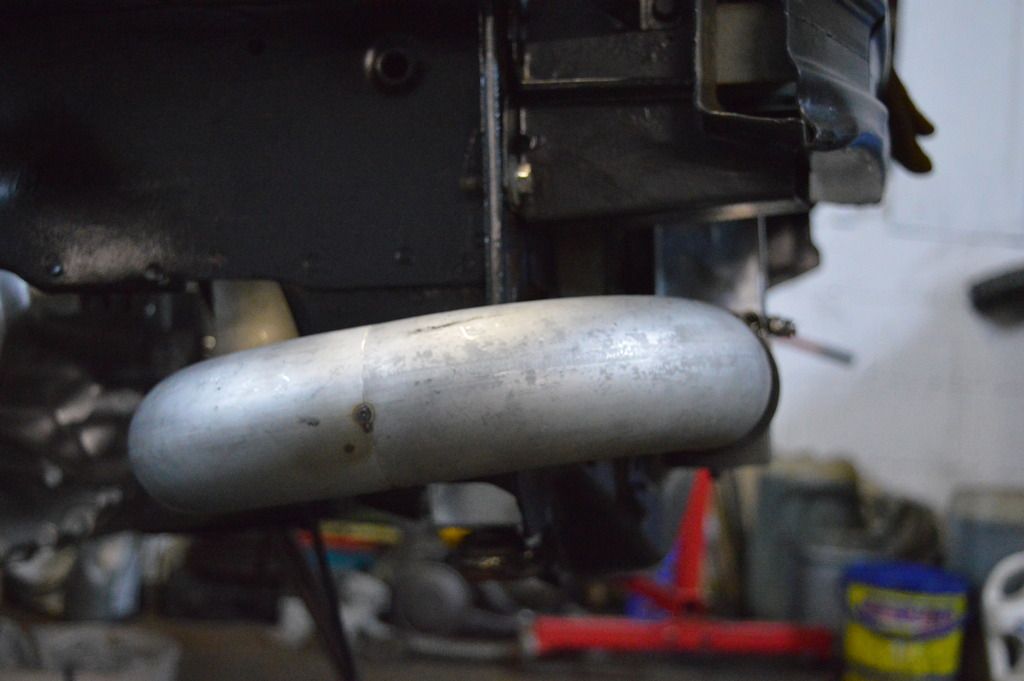

We have sussed the hot side and all we need to do is add about 5 inches of 2'' pipe onto what you can see in the pictures and that will be done

Here is what we pretty much started with.

And here is the cold side tacked together.

And this is the hot side.

We should have the intercooler pipework finished off this weekend then its onto the next thing, wiring!

Thanks for looking

Ben

I'd say that would be a blast to drive.

I'd say that would be a blast to drive.