You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EK9 Racecar

- Thread starter B16Swt

- Start date

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

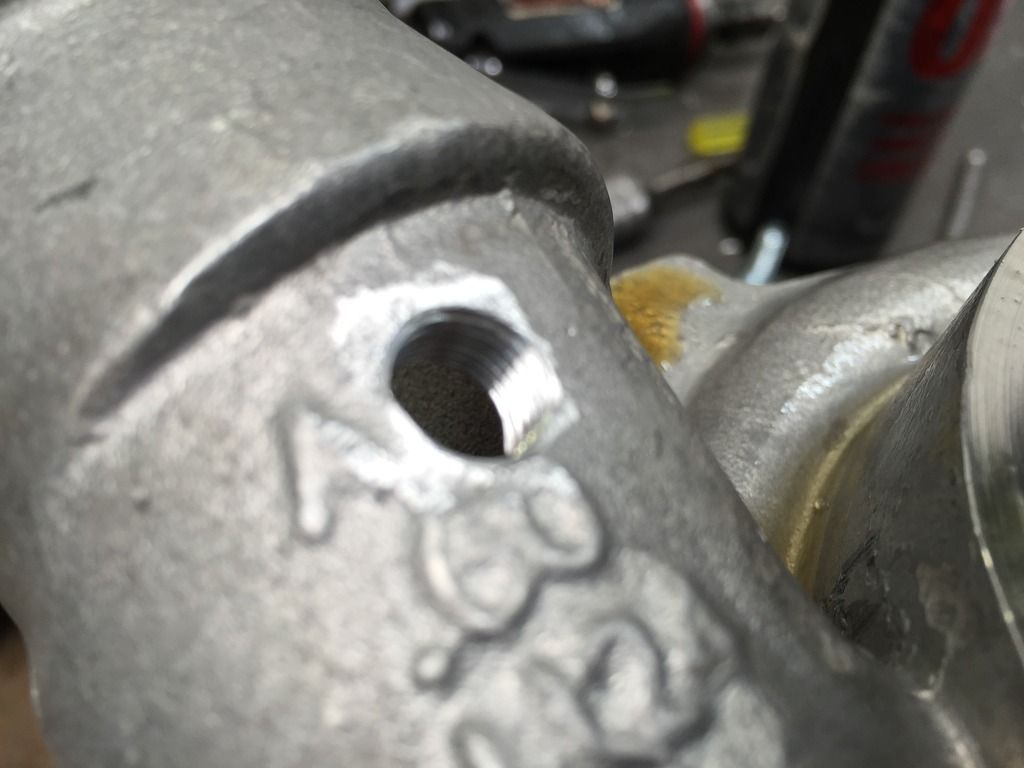

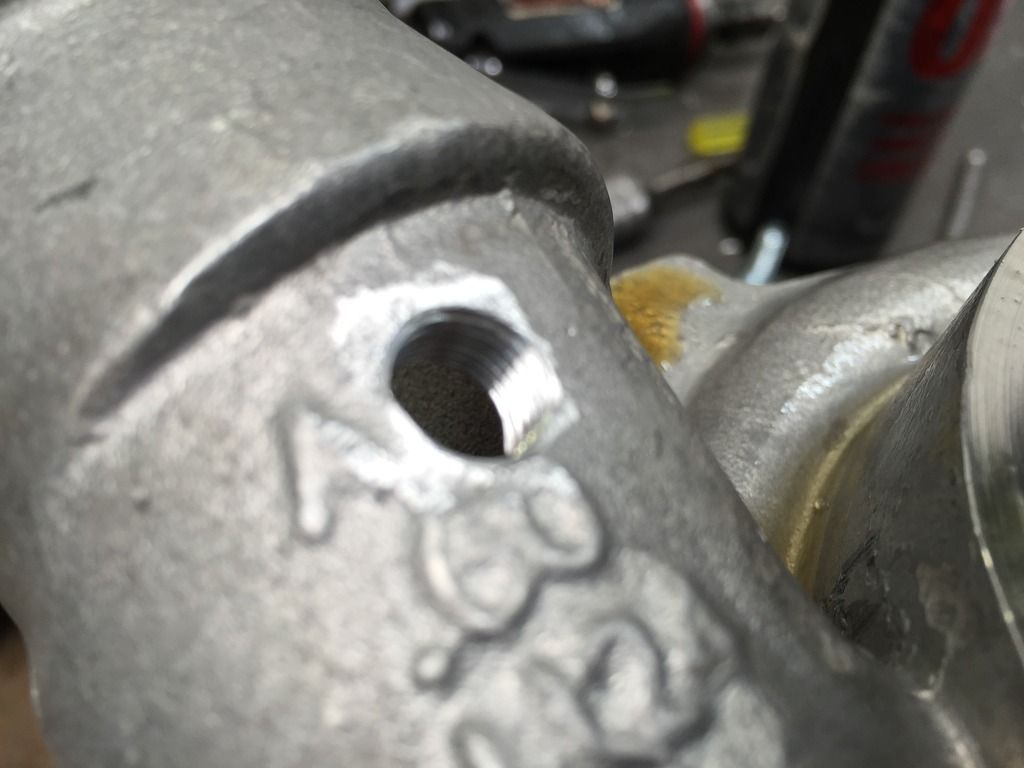

Had a bit of a set back today  I was tightening up the bolts for the compressor housing, and one bolt was tightening a bit easier than the others.

I was tightening up the bolts for the compressor housing, and one bolt was tightening a bit easier than the others.

Anyway before it was anywhere near tight the bolt head sheared clean off!!!!

All I can put it down to is a sub standard bolt? If I'd over tightened it the threads in the alluminium housing should of stripped before the bolts snapped. Really annoying, cause it means I have to take the compressor housing off a brand new turbo to get the rest of the bolt out

@jesse888 i shouldn't do any harm taking the housing off?

Anyway before it was anywhere near tight the bolt head sheared clean off!!!!

All I can put it down to is a sub standard bolt? If I'd over tightened it the threads in the alluminium housing should of stripped before the bolts snapped. Really annoying, cause it means I have to take the compressor housing off a brand new turbo to get the rest of the bolt out

@jesse888 i shouldn't do any harm taking the housing off?

- Joined

- Oct 16, 2012

- Messages

- 8,917

No harm taking it off at all. Tbh I'd recommend tapping a port hole for your boost control solenoid/wastegate plumbing whilst it's off. The compressor housing is the best place for it although I have mine in a silicone hose that just exits the turbo.

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

Cool man, I'll do that. I'd imagine having the vacuum port on the housing you'll get the best vacuum to the solenoid with no delay? Rather than going off the inlet manifold.No harm taking it off at all. Tbh I'd recommend tapping a port hole for your boost control solenoid/wastegate plumbing whilst it's off. The compressor housing is the best place for it although I have mine in a silicone hose that just exits the turbo.

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

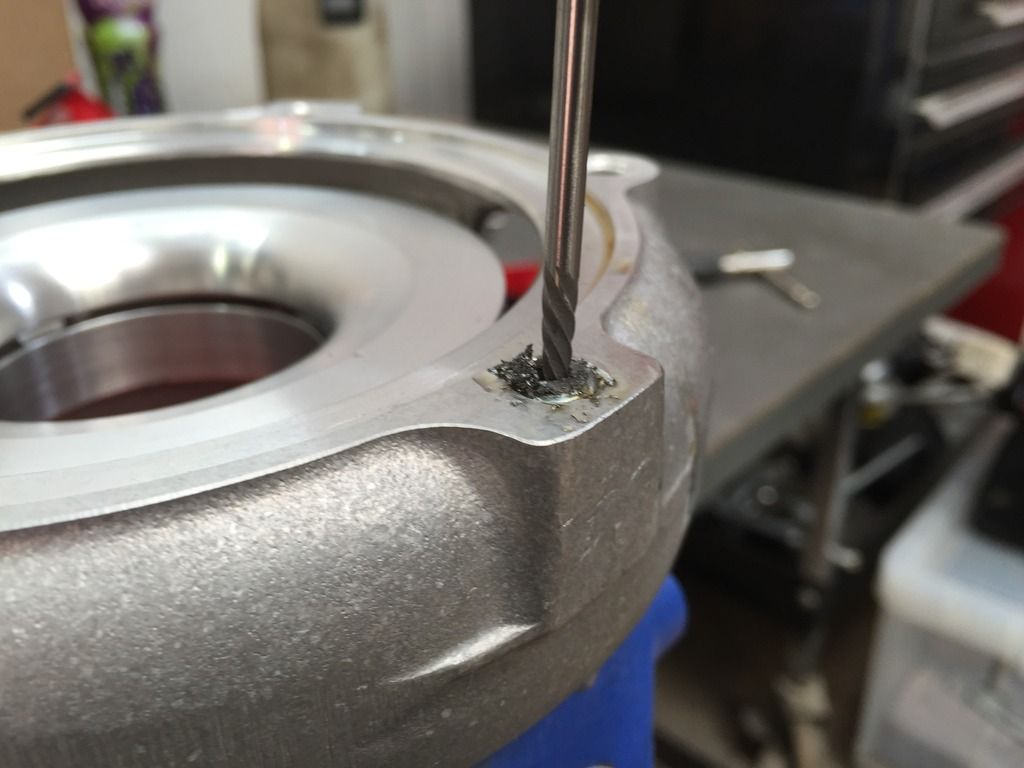

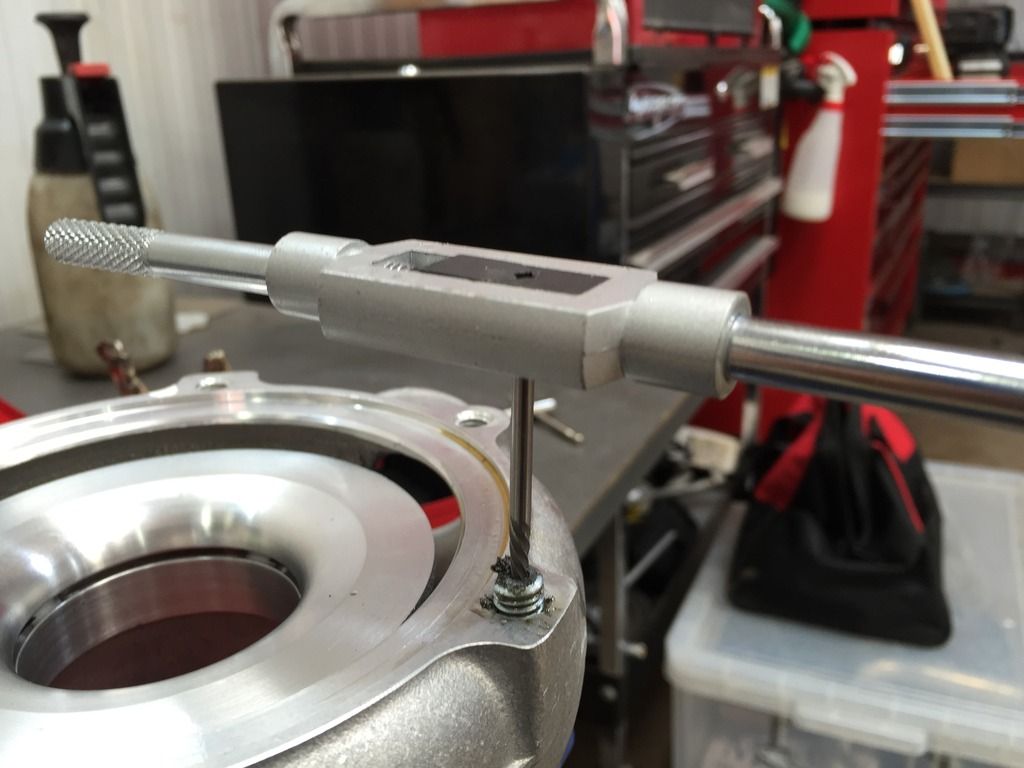

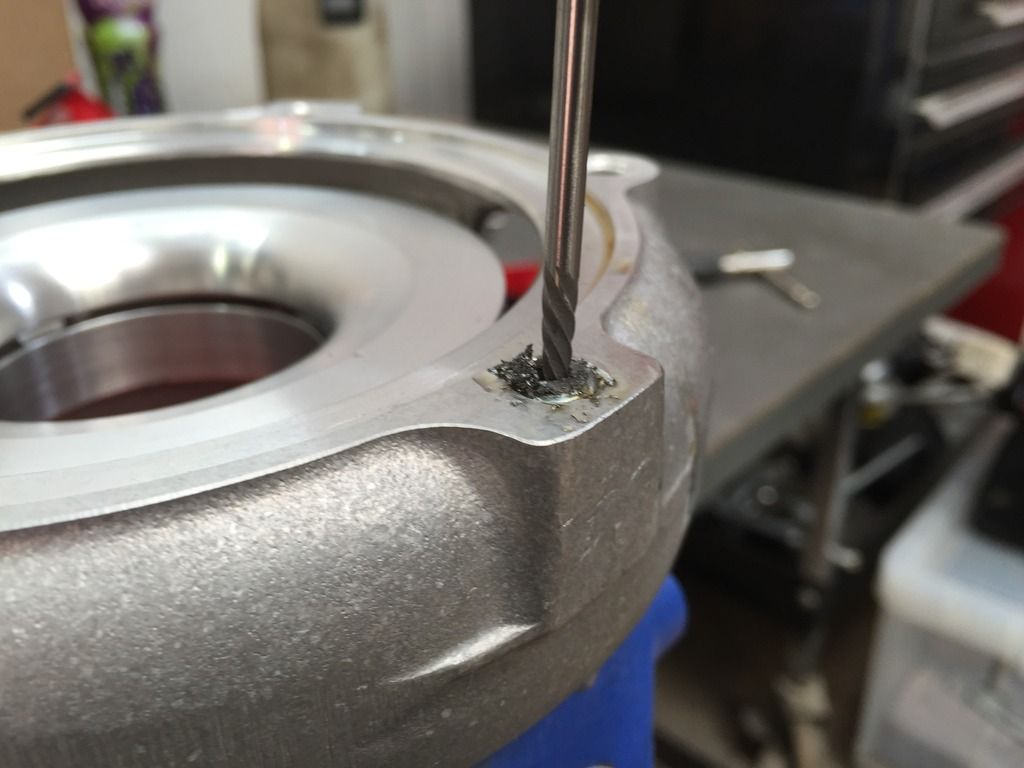

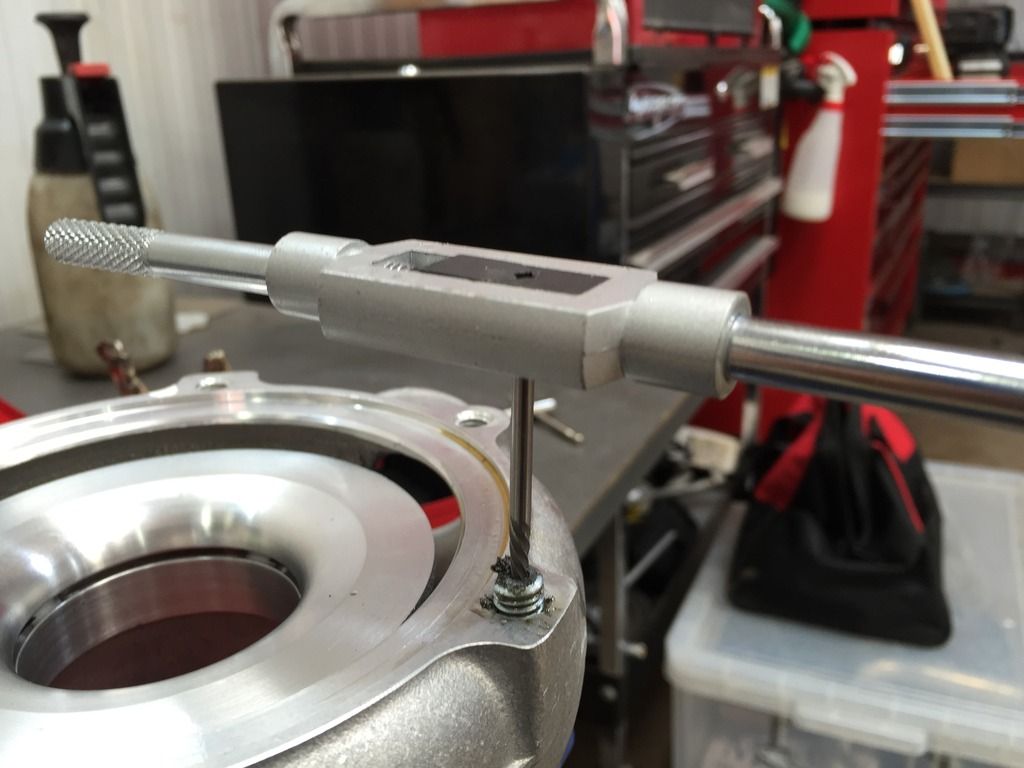

Had better luck today! I managed to get the snapped bolt out the compressor housing.

I had re-tap the thread to a m8x1.25 so I could use an normal m8bolt.

Jobs a good'n!

Then I put in an outlet for the boost solenoid.

Using a 1/8npt tap, tapped into the housing and used a spare 1/8 outlet, sealed in with arp thread sealer which is basically liquid ptfe tape.

What do you guys think?

Also managed to sort out the oil filter housing issue. Thanks to everyone that helped with my post earlier today! Really appreciate it!!

I had re-tap the thread to a m8x1.25 so I could use an normal m8bolt.

Jobs a good'n!

Then I put in an outlet for the boost solenoid.

Using a 1/8npt tap, tapped into the housing and used a spare 1/8 outlet, sealed in with arp thread sealer which is basically liquid ptfe tape.

What do you guys think?

Also managed to sort out the oil filter housing issue. Thanks to everyone that helped with my post earlier today! Really appreciate it!!

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

Pretty sure it's 67mm, I'll have a measure tomorrow to be sure.Yeah that's perfect Sam.

What's the size of the inlet on your compressor housing? Looks alittle smaller than mine is all.

Mine is 3"

- Joined

- Apr 15, 2006

- Messages

- 10,695

- Car(s)

- EK9/Civic

Had better luck today! I managed to get the snapped bolt out the compressor housing.

I had re-tap the thread to a m8x1.25 so I could use an normal m8bolt.

Jobs a good'n!

Then I put in an outlet for the boost solenoid.

Using a 1/8npt tap, tapped into the housing and used a spare 1/8 outlet, sealed in with arp thread sealer which is basically liquid ptfe tape.

What do you guys think?

Also managed to sort out the oil filter housing issue. Thanks to everyone that helped with my post earlier today! Really appreciate it!!

Amazing!

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

It's exactly 3" mate, maybe it's just the picture that makes it look smallPretty sure it's 67mm, I'll have a measure tomorrow to be sure.

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

So the oil feed and return lines are on the turbo, same with the water inlet and outlet.

The turbo is now on the manifold, mocking up where I'm going to install the water lines, I found a good article by Garrett on the importance of watercooling / thermo siphoning and how to route lines etc, I'm going to use the top and the bottom of the radiator because of its location and the radiator is easy to modify.

I also have the Tial MVR wastegate that is water cooled, so I'm going to plumb that into the radiator too. From what I've read people are 50/50 on the idea. But from what I can make out it's the smallest wastegate on the market, so therefore doesn't dissipate heat as well, so water cooling is added to help, plus like the turbo after the engine is switched off you'll get heat soak which will distroy seals etc quicker.

Anyone else using a water cooled waste gate?

Will put more pictures up soon

The turbo is now on the manifold, mocking up where I'm going to install the water lines, I found a good article by Garrett on the importance of watercooling / thermo siphoning and how to route lines etc, I'm going to use the top and the bottom of the radiator because of its location and the radiator is easy to modify.

I also have the Tial MVR wastegate that is water cooled, so I'm going to plumb that into the radiator too. From what I've read people are 50/50 on the idea. But from what I can make out it's the smallest wastegate on the market, so therefore doesn't dissipate heat as well, so water cooling is added to help, plus like the turbo after the engine is switched off you'll get heat soak which will distroy seals etc quicker.

Anyone else using a water cooled waste gate?

Will put more pictures up soon

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

I didn't water cool my gate. It took a while but eventually I lost a seal. Going through the process of plumbing the coolant into it now to avoid these issues.

Yeh I saw that you were having seal problems. From what I've read the damage is done when the engine and turbo is hot with the engine not running. Hopefully the thermo siphone effect will save the seals.

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

So got a fair bit done today ).gif)

First was to refit the lower timing cover after modifying it to fit this........

I decided in the end that it would be money very well spent and will give me piece of mind.

Thanks to everyone's input on the damper

Clever bit of kit and looks the nuts too, it's a lot heavier than I thought it would be!

Next up I did the valve clearances, 19 thou inlet 21 thou exhaust.

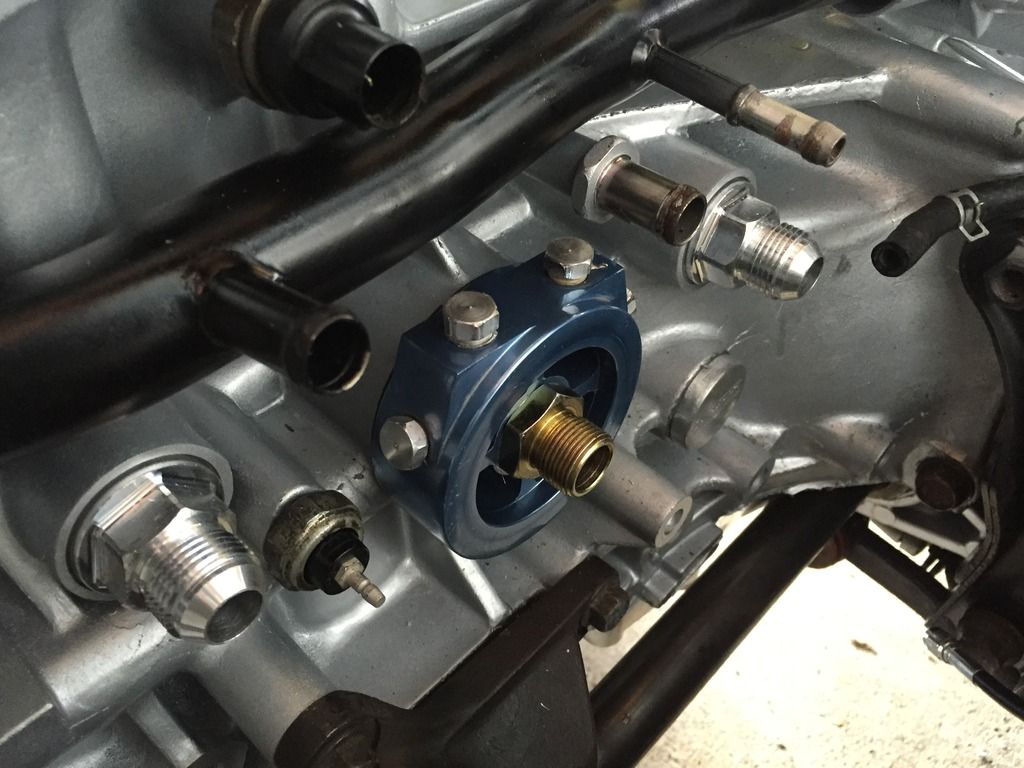

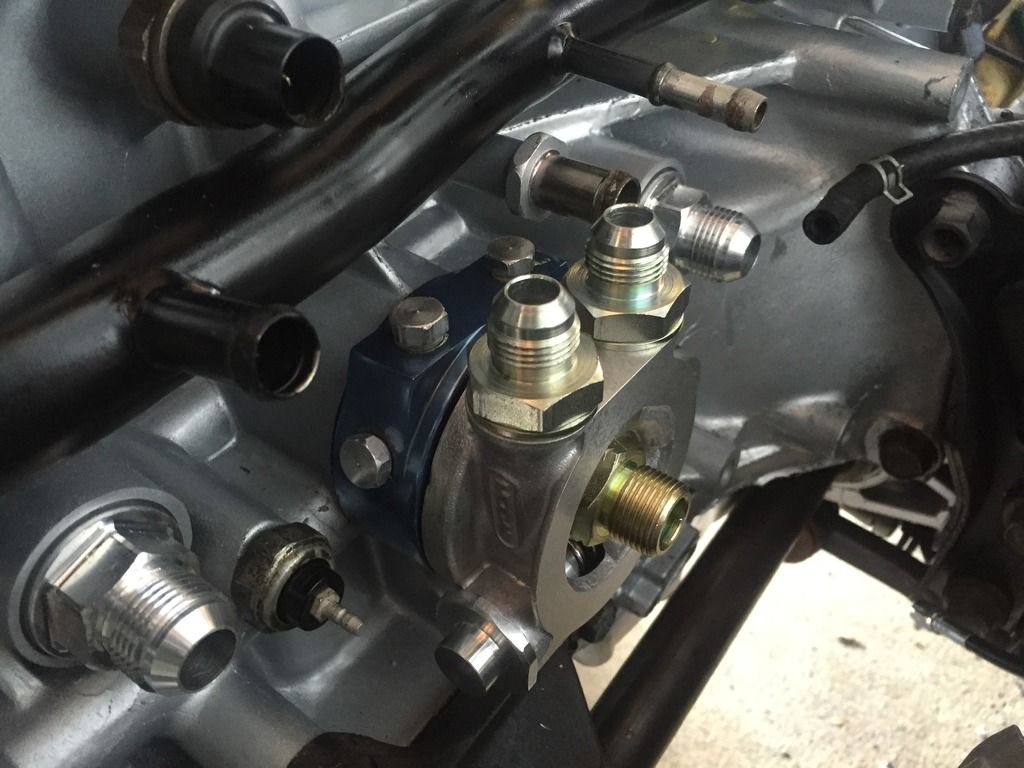

I've also sorted the leaning tower of sandwich plates! I wasn't keen on having 3 plates, so I came up with this.

I wasn't keen on having 3 plates, so I came up with this.

I'm using the stock oil pressure switch hole in the block to feed the turbo with oil, and to feed the oil pressure sensor.

I could then loose a plate, and put the stock pressure switch and temp sensor on the first plate, then that gives the clearance for the Mocal thermostatic plate. Really happy with it. I used PTFE on all the threads just to be sure.

Oil cooler lines in, just need to get some P clips / cable ties to make them neat.

Breather can is on and all lines plumbed.

Will get better pictures soon.

Oil return for turbo, I'm going to redo it as I'm not 100% happy with it.

Next up is to sort the wiring around the back of the engine, then Inlet manifold on.

And next weeks task at work is to modify the radiator to take some AN6 and AN4 unions.

).gif)

First was to refit the lower timing cover after modifying it to fit this........

I decided in the end that it would be money very well spent and will give me piece of mind.

Thanks to everyone's input on the damper

Clever bit of kit and looks the nuts too, it's a lot heavier than I thought it would be!

Next up I did the valve clearances, 19 thou inlet 21 thou exhaust.

I've also sorted the leaning tower of sandwich plates!

I wasn't keen on having 3 plates, so I came up with this.

I wasn't keen on having 3 plates, so I came up with this.I'm using the stock oil pressure switch hole in the block to feed the turbo with oil, and to feed the oil pressure sensor.

I could then loose a plate, and put the stock pressure switch and temp sensor on the first plate, then that gives the clearance for the Mocal thermostatic plate. Really happy with it. I used PTFE on all the threads just to be sure.

Oil cooler lines in, just need to get some P clips / cable ties to make them neat.

Breather can is on and all lines plumbed.

Will get better pictures soon.

Oil return for turbo, I'm going to redo it as I'm not 100% happy with it.

Next up is to sort the wiring around the back of the engine, then Inlet manifold on.

And next weeks task at work is to modify the radiator to take some AN6 and AN4 unions.

Hi there! Awesome build. Just out of interest, how much was it for the Go autoworks manifold and down pipe? I have a pfab manifold and down pipe but the manifold has cracked several times. I have limited space as run a full length race radiator and use power steering. This looks perfect fit for mine if 3 inch

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

Hi there! Awesome build. Just out of interest, how much was it for the Go autoworks manifold and down pipe? I have a pfab manifold and down pipe but the manifold has cracked several times. I have limited space as run a full length race radiator and use power steering. This looks perfect fit for mine if 3 inch

Hello! I'm not sure exactly as I bought it in kit form. If you message go-autoworks they'd be happy to give you a price. They're usually good with replying.

And yes it's a 3" downpipe.

- Joined

- Sep 27, 2015

- Messages

- 1,492

- Car(s)

- Ek9

Valve clearances should be .006-.007 thou for inlet and .007-.008 for exhaust?

Unless you mean mm?

Oh right, some info I found said .019 inlet and .021 exhaust.

That is with the engine cold.

.007 / .008 seems quite tight when cold?

Thanks for the info will look into it