You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

98 spec Integra Type R

- Thread starter db-89

- Start date

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

Thanks man,really appreciate itawesome work on the restoring, hopefully back to shows soon

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

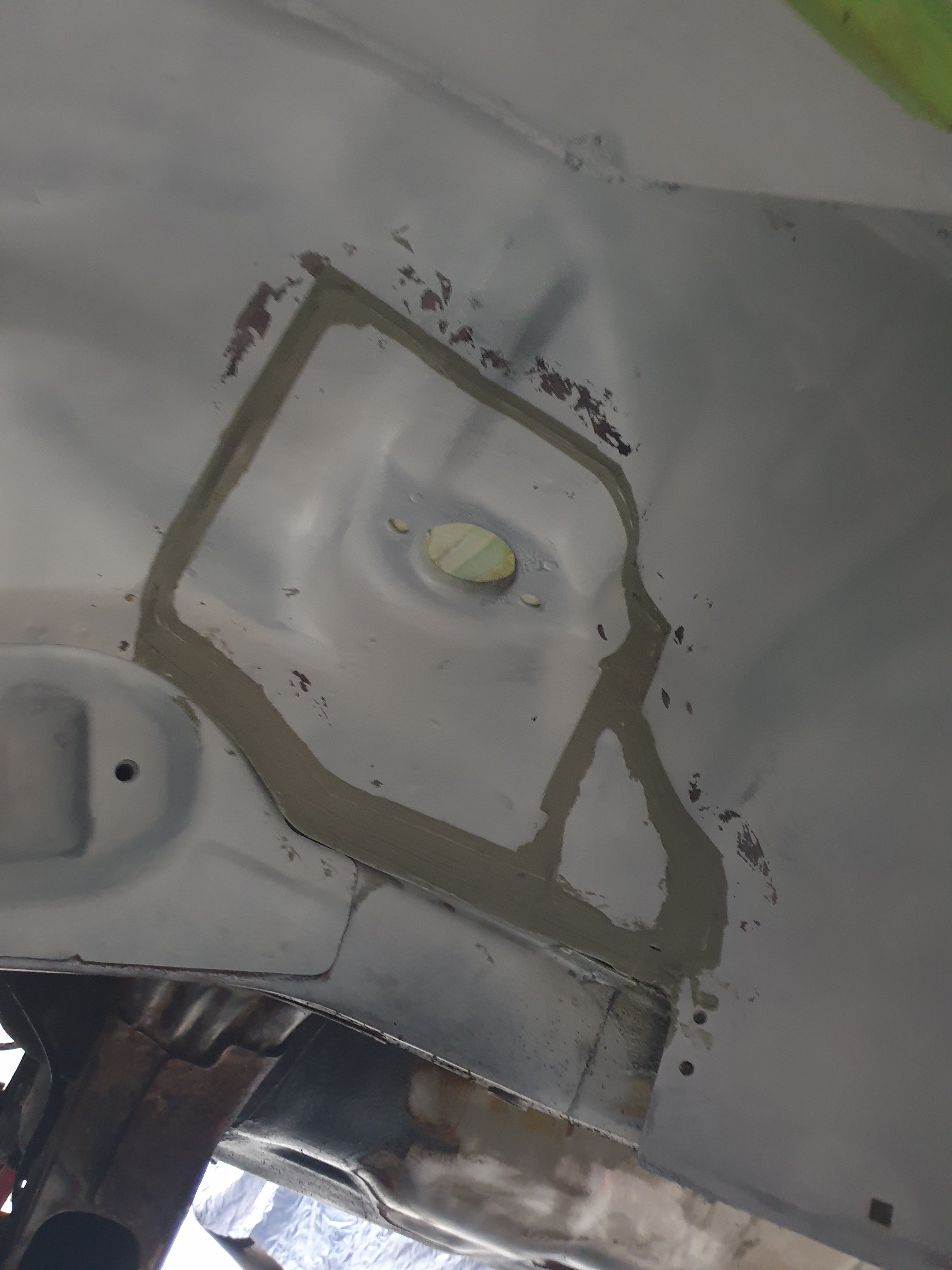

Late start today but got the tank down and most of the left arch cleaned back. Started some of the boot floor aswell.

All good above the tank,all dry surface rust thankfully. Some seam sealer applied on rear left after epoxy 1k primer

Started on the boot floor and rear chassis leg so hopping tomorrow ill have the boot floor done and a start on the other arch

All good above the tank,all dry surface rust thankfully. Some seam sealer applied on rear left after epoxy 1k primer

Started on the boot floor and rear chassis leg so hopping tomorrow ill have the boot floor done and a start on the other arch

Dcharles_Ek9

Active Member

- Joined

- Jan 20, 2023

- Messages

- 69

- Car(s)

- 98 Civic Type R/96 Integra Type R DB8

Love a good rebuild thread! Gives me motivation to fully strip my EK down to the shell in the next year.

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

Thanks man,its a lot of work. I wanted to start it during covid but I had to build a pro spec drift car and my own car in 6 weeks then. Regret not getting more parts then as alot is getting so hard to find.Love a good rebuild thread! Gives me motivation to fully strip my EK down to the shell in the next year.

If you even do a corner of the underbody at a time it'll make the difference and takes the pressure off

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

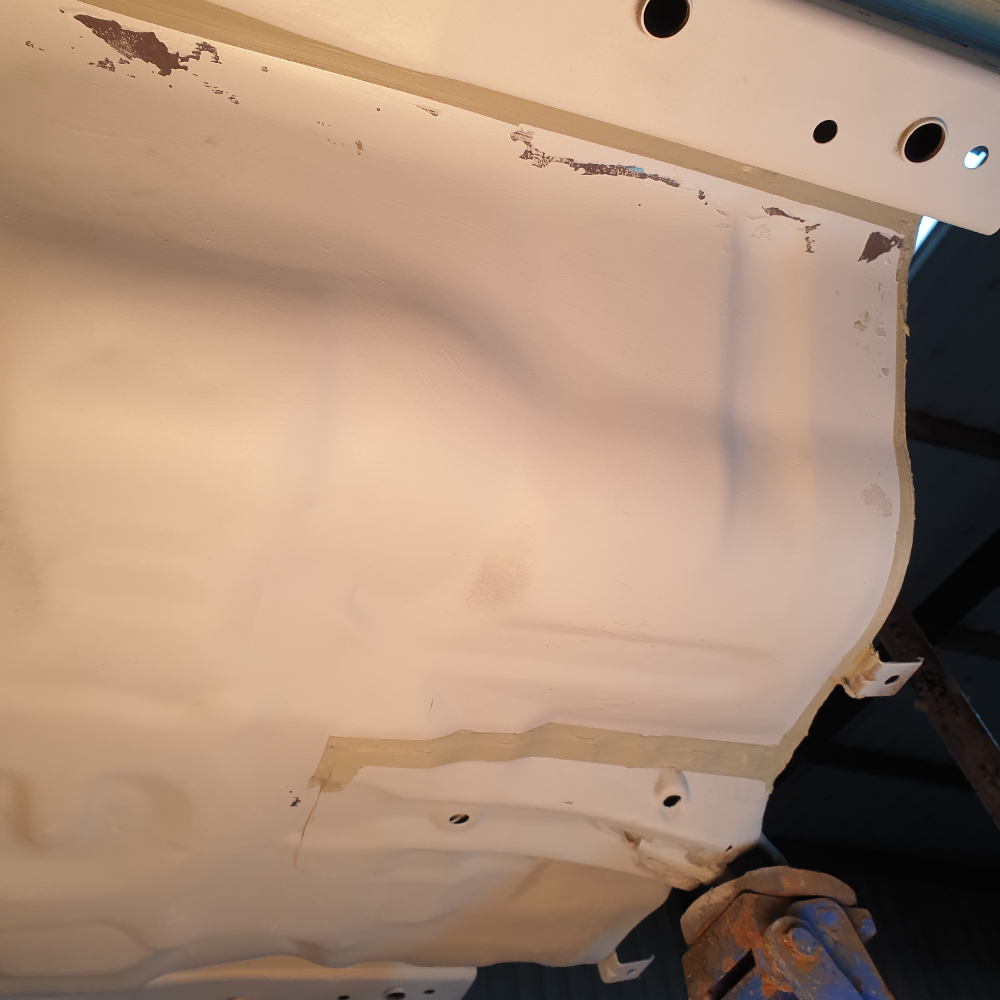

Got a bit more done on Friday, have the boot floor in epoxy and the left side is all in sealer. Rear panel is now in its first coat of high zinc epoxy primer.

Back to work next week so probably only going to gat a day each week at it now. Important part is that its started

Everything was brought back to bare metal,some areas had factory sealer covered in multiple layers of black shutz which did preserve the metal but looked like dung and was a nightmare to remove. I'm using an m18 milwaukee grinder with the 8amp battery and a knotted cup brush,when it hits the black stuff its like hitting the brakes. I sprayed some petrol on and it did soften it but I found a low flow butane torch made the biggest difference to soften it.

When it was back to metal I used bardahl convert,ox on any surface rust areas but also any metal incase of microscopic rust pores i can't see. I then put on a dust coating of pro xl epoxy 1k and 2 thick coats before seal sealer. After this I will put on a thick coat of high zinc epoxy before 2 coats of white stone guard and then QD enamel paint in champ white. Im doing this once and want it to last

Back to work next week so probably only going to gat a day each week at it now. Important part is that its started

Everything was brought back to bare metal,some areas had factory sealer covered in multiple layers of black shutz which did preserve the metal but looked like dung and was a nightmare to remove. I'm using an m18 milwaukee grinder with the 8amp battery and a knotted cup brush,when it hits the black stuff its like hitting the brakes. I sprayed some petrol on and it did soften it but I found a low flow butane torch made the biggest difference to soften it.

When it was back to metal I used bardahl convert,ox on any surface rust areas but also any metal incase of microscopic rust pores i can't see. I then put on a dust coating of pro xl epoxy 1k and 2 thick coats before seal sealer. After this I will put on a thick coat of high zinc epoxy before 2 coats of white stone guard and then QD enamel paint in champ white. Im doing this once and want it to last

Last edited:

Civicfacelift

ej9, eg6 , ep3

- Joined

- Jan 15, 2011

- Messages

- 682

great work, will be immaculate when its all done !

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

A few weeks away from the car due to metal in my eye and alot of work fatigue,hopefully back at it this week.

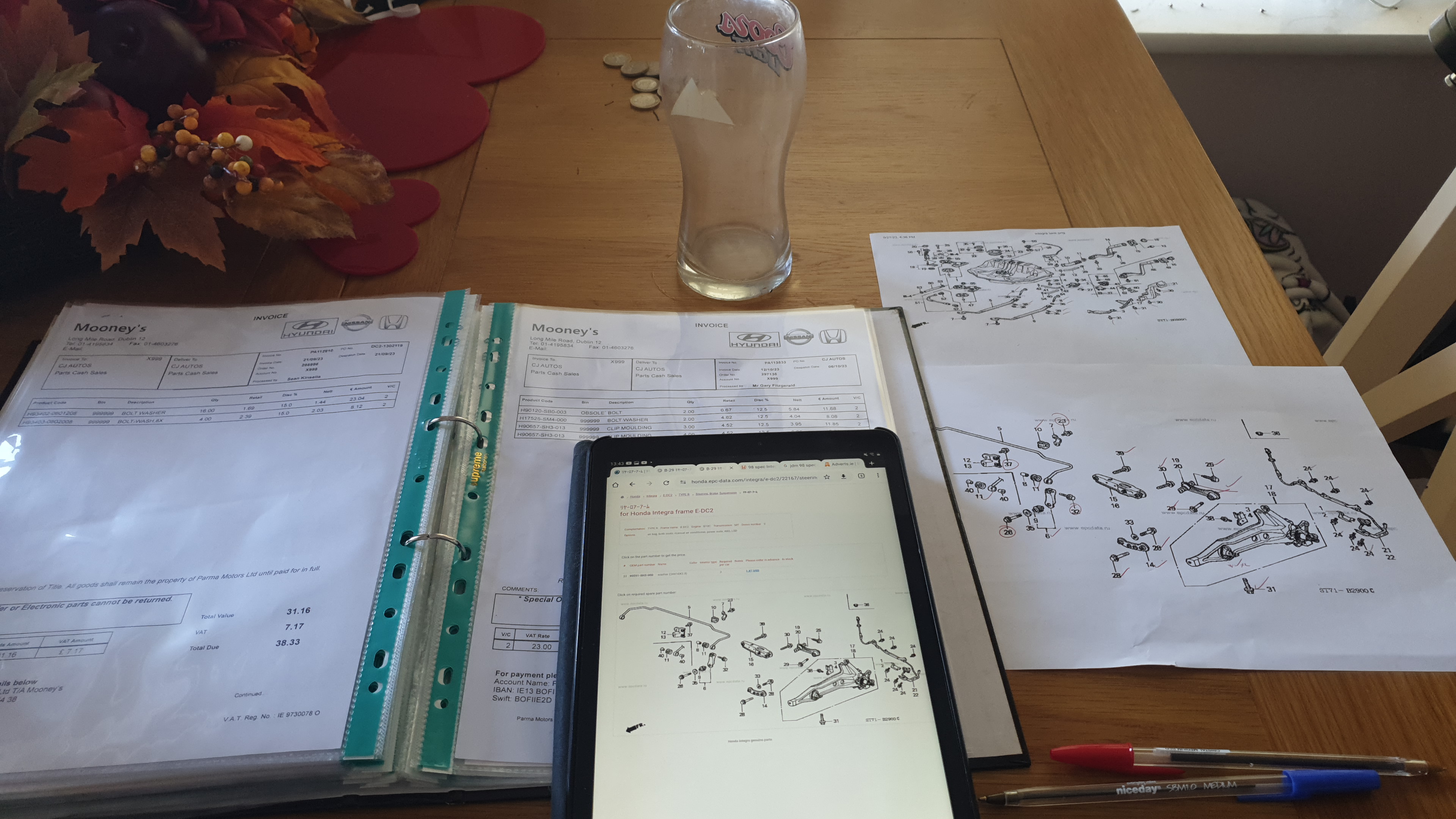

Sorted some service history and accounted for what bits iv bought

Got some more OEM bolts and clips for the back end

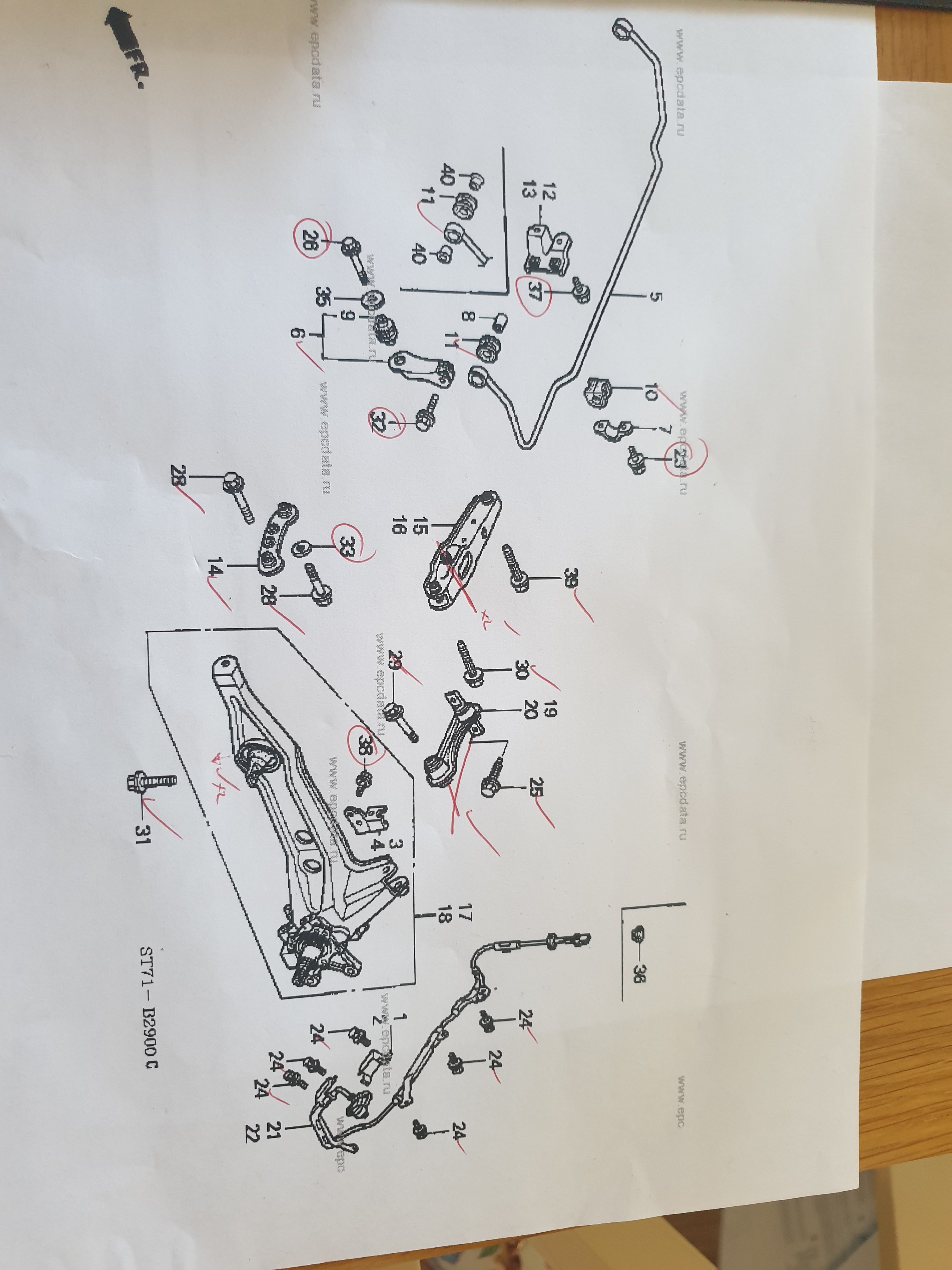

Bought some hardrace rear roll bar bushes as oem jdm size inners were no longer available

And won a set of 98 spec OEM JDM rear mudflaps after searching for a number of years to get a clean set

Sorted some service history and accounted for what bits iv bought

Got some more OEM bolts and clips for the back end

Bought some hardrace rear roll bar bushes as oem jdm size inners were no longer available

And won a set of 98 spec OEM JDM rear mudflaps after searching for a number of years to get a clean set

Last edited:

iRELOADED

Jordan 258

- Joined

- Oct 11, 2013

- Messages

- 651

- Car(s)

- Civic Jordan 258

Thats always a bugger. Hopefully they got it out easy enough without that glow dye stuff?A few weeks away from the car due to metal in my eye and alot of work fatigue,hopefully back at it this week.

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

Not this time thank god but did use numbing gel so had to sit outside for an hour before driving after waiting 8 hoursThats always a bugger. Hopefully they got it out easy enough without that glow dye stuff?

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

Got the rear right arch into primer. The inner lip of the arch needs attention but nowhere as bad as I expected thankfully.

The usual stripped back to metal,treated with de oxidiser then a thick coat of novol epoxy primer

Just for comparison,I'm size 13 shoes and thats one the amount of crap from one arch,approx 2 inches thick

My hord of engine parts so far

Rear suspension hord so far

The usual stripped back to metal,treated with de oxidiser then a thick coat of novol epoxy primer

Just for comparison,I'm size 13 shoes and thats one the amount of crap from one arch,approx 2 inches thick

My hord of engine parts so far

Rear suspension hord so far

db-89

Active Member

- Joined

- May 28, 2017

- Messages

- 107

- Car(s)

- DC2. E36

Haven't had much time at this in the last 6 months due to working hours and living an hour away from the car.

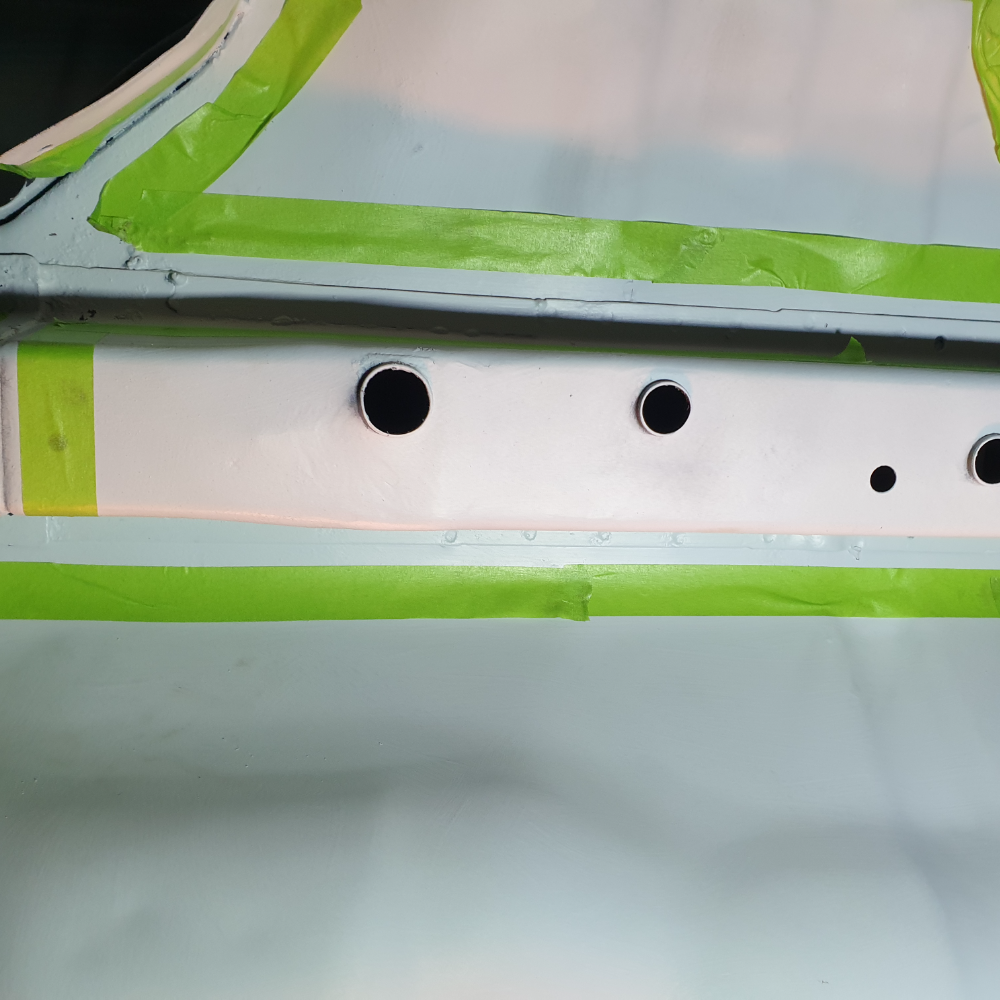

all sealer has been removed as far as the rear floor pan area.

I **** out the 5 sections of rust on the sills and had a friend make me up a sill section for repairs.

strangely enough the sill have expanding foam in them but appears to have been in before any rust. The rust hasn't been severe enough to fill with foam but iv been told by a number of people that this was done in Japan to stiffen the shell. Not sure how good it is at that but I can definitely say its a bastard to remove

Some minor parts to be fabricated inside but nothing too bad. Interior is all out so its going to be done right.

All above the fuel tank area has been brought back to bare metal,treated with brunnox epoxy rust converter and inhibitor. Another layer of high zinc epoxy primer is put on and then the spray on seam sealer is applied.

all sealer has been removed as far as the rear floor pan area.

I **** out the 5 sections of rust on the sills and had a friend make me up a sill section for repairs.

strangely enough the sill have expanding foam in them but appears to have been in before any rust. The rust hasn't been severe enough to fill with foam but iv been told by a number of people that this was done in Japan to stiffen the shell. Not sure how good it is at that but I can definitely say its a bastard to remove

Some minor parts to be fabricated inside but nothing too bad. Interior is all out so its going to be done right.

All above the fuel tank area has been brought back to bare metal,treated with brunnox epoxy rust converter and inhibitor. Another layer of high zinc epoxy primer is put on and then the spray on seam sealer is applied.