lazybean

Member

- Joined

- Apr 28, 2010

- Messages

- 416

Ok guys got a bit of an issue here.

Ill explain the situation as well as i can.

The car started off as an EK3 so small front calipers and rear drums.

I have swapped out to 282mm 98 spec UK Integra brakes front and the rear brakes from the same car.

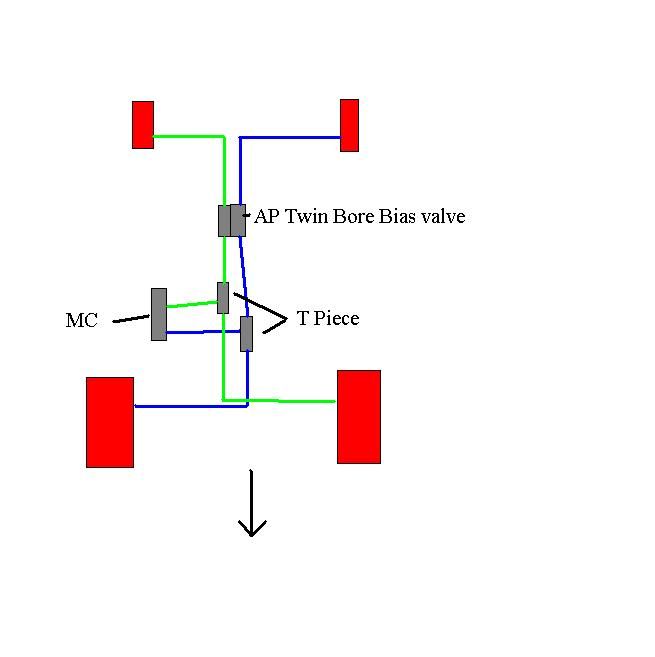

I have got rid of the ABS and proportioning valve and installed a rear bias instead.

I have no leaks and have bled the brakes a few times, there is no air in the system (that i'm aware of). The brakes feel OK without the engine running.

When the engine is on the pedal just drops to the floor, very little resistance.

When i roll the car around the back garden, I can get the car to brake but it doesn't lock quick at all, it just slowly comes to a stop with my foot to the ground.

Here are some pictures of the setup.

What is going on here?

Not sure what im doing wrong? or is this ok? does it need to be driven around for a while?

Ill explain the situation as well as i can.

The car started off as an EK3 so small front calipers and rear drums.

I have swapped out to 282mm 98 spec UK Integra brakes front and the rear brakes from the same car.

I have got rid of the ABS and proportioning valve and installed a rear bias instead.

I have no leaks and have bled the brakes a few times, there is no air in the system (that i'm aware of). The brakes feel OK without the engine running.

When the engine is on the pedal just drops to the floor, very little resistance.

When i roll the car around the back garden, I can get the car to brake but it doesn't lock quick at all, it just slowly comes to a stop with my foot to the ground.

Here are some pictures of the setup.

What is going on here?

Not sure what im doing wrong? or is this ok? does it need to be driven around for a while?