You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DC2 ITR K24 Frankenstein Build (DYNO Result)

- Thread starter muiris

- Start date

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

It's a tidy car & i intended to run the B18C for a while. However, it was smoking a bit on WOT, so i replaced the valve stem seals. This didn't fix the smoke, so i had the head rebuilt professionally (new headgasket, skim, new exhaust valves, valve guides etc). After this rebuild (at considerable expense) the car smoked worse than ever.

I was told that this may happen after a head is rebuilt (shows weak piston rings, oil sucked out exhaust port). I looked into a full rebuild but this would easily be 3K. At this point i was sick & tired of dealing with this engine so decided to sell it & go K series. The diehards will hate doing this to a type r but there's only so much a person can take.

The B18C:

And so the build begins:

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

The Engine:

- K24a JDM bottom end, weld in baffled sump.

- K20 Head (RSP), this is the best flowing head of all the K20 engines. Found on FD2 & FN2.

- K20 Oil pump

- 50 Degree Cam gear with 40 Degree VTC limiter pin (tactruff).

- Drag Cartel Drop in cams.

- Head refresh (stem seals, retainers & keepers, LMAs).

- RRC Intake Manifold (FD2)

- K tuned alternator relocation & PS delete ( i will be using electro Hyrdo set up)

- OEM 410cc RDX Injectors, Walbro 255LPH pump, AEM Regulator, K-Tuned Fuel rail with custom lines.

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

One of the first steps after the mighty B18c was pulled was to take out the drivers side engine mount bracket. 8mm spot weld drill bit was useful along with hammer & chisel.

Off: Area ground down, filled & painted.

After:

Another Job is fuel line preparation. Need to go from hardline to -AN6 lines. Easier to get these prepped while engine is out.

You do this for both feed & return. Feed is larger diameter so easy to identify.

Off: Area ground down, filled & painted.

After:

Another Job is fuel line preparation. Need to go from hardline to -AN6 lines. Easier to get these prepped while engine is out.

You do this for both feed & return. Feed is larger diameter so easy to identify.

Dcharles_Ek9

Active Member

- Joined

- Jan 20, 2023

- Messages

- 69

- Car(s)

- 98 Civic Type R/96 Integra Type R DB8

Loved that you tried to keep the b18c but the universe gave you a sign.lol. Look forward to seeing the outcome.

Nathan Brooks

Heaveh foot

- Joined

- Jun 13, 2018

- Messages

- 238

- Car(s)

- JDM H22A Swap EK Civic

K20a head from a FD2R? Thats gonna be a banger!

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

Thanks for the comments guys

Some good progress made today.

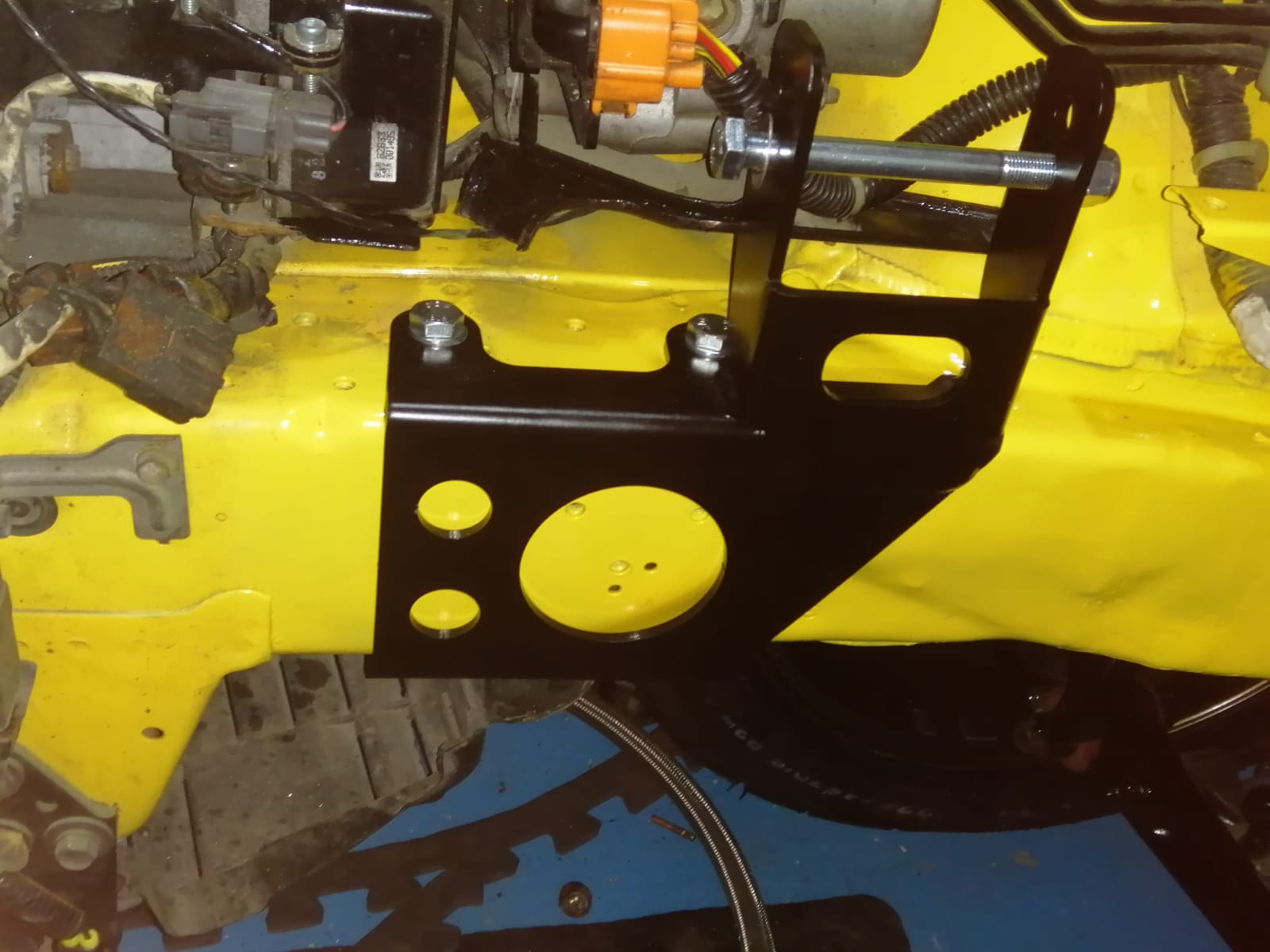

Hasport Engine Mounts Arrived!

These are dual height, meaning you can mount a K20 or K24.

Installed drivers side mount:

Rear mount:

Engine Installed finally, this was installed from the top using an engine crane. Would be alot easier if you have a car lift to drop the car onto the engine.

I'll be moving onto the wiring next.

I'll be moving onto the wiring next.

Some good progress made today.

Hasport Engine Mounts Arrived!

These are dual height, meaning you can mount a K20 or K24.

Installed drivers side mount:

Rear mount:

Engine Installed finally, this was installed from the top using an engine crane. Would be alot easier if you have a car lift to drop the car onto the engine.

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

One thing I forgot to mention, if you're using a K24A that was an automatic (alot of them were in Japan), the flywheel bolts are shorter on the automatic. Both will fit but you run the risk of them backing out & destroying your crank/oil pump. Use the manual K20 bolts instead.

Picture for reference:

Picture for reference:

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

Now that the engine is in, i did i few small jobs.

Took the engine harness in through the firewall.

Cut the heater hoses to length & made a small heat shield for the plastic valve.

Made a bracket to mount AEM FPR. Ran AN -6 hose to rail.

Installed Clutch slave cylinder & Hybrid Racing steel braided line.

Engine as it stands now.

Took the engine harness in through the firewall.

Cut the heater hoses to length & made a small heat shield for the plastic valve.

Made a bracket to mount AEM FPR. Ran AN -6 hose to rail.

Installed Clutch slave cylinder & Hybrid Racing steel braided line.

Engine as it stands now.

Nathan Brooks

Heaveh foot

- Joined

- Jun 13, 2018

- Messages

- 238

- Car(s)

- JDM H22A Swap EK Civic

Yeah alot of the flywheel bolts for automatic are a bit short and more time when ever doing a flywheel job, they usually require you change them out just for safety shakeOne thing I forgot to mention, if you're using a K24A that was an automatic (alot of them were in Japan), the flywheel bolts are shorter on the automatic. Both will fit but you run the risk of them backing out & destroying your crank/oil pump. Use the manual K20 bolts instead.

Picture for reference:

View attachment 49016

spikeyhairdude

Vishal

- Joined

- Nov 20, 2011

- Messages

- 1,455

- Car(s)

- EK9/E82

Make sure You get the spigot bearing that goes in the middle of the crank and flywheel area as automatics dont come with them also.

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

Yep, should have said that as-well. Spigot/ pilot bearing came with new clutch with a big warning on the package saying warranty void if bearing not installed. Thanks.Make sure You get the spigot bearing that goes in the middle of the crank and flywheel area as automatics dont come with them also.

Another job completed. Oil cooler rad installed along with Mocal thermostatic plate.

spikeyhairdude

Vishal

- Joined

- Nov 20, 2011

- Messages

- 1,455

- Car(s)

- EK9/E82

I love a clean oil cooler setup. Thats brilliant

muiris

Well-Known Member

- Joined

- Nov 23, 2009

- Messages

- 1,430

Thanks man.I love a clean oil cooler setup. Thats brilliant

Few more small jobs done.

Made a small alu plate to fit in front of shifter. Put a 5v USB charger for my phone in it using existing cigarette wiring.

Put some wrap over it:

Installed along with Hybrid Racing Shifter & shifter plate:

Also finished wring the ECU (Doctronic ProEcu-K) into adapter harness. Also gutted the AC box:

Will be going to try to start it in the next few days