You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

B16A rebuild project

- Thread starter ek4 hatchback

- Start date

- Joined

- Jun 5, 2007

- Messages

- 6,222

Seems like a good alternative to get the CR up providing clearance is good.

yep but there heavy pistons

ek4 hatchback

Active Member

- Joined

- Oct 28, 2008

- Messages

- 357

The compression height on the CTR pistons is 0.73mm more than b16a, which will put it around 0.2mm higher than the b16a block (You could measure this with a DTI to get accurate figure). Ideally you need 1mm piston to head clearance. 3 layer gasket is approx 0.7mm, so be carefull.Ideally you need to clay the engine, as i think your geting tight on your tolerances! I think your CR with these pistons alone in the b16a will be around the 12:1 mark. I think a critical measurement will be the head face to chamber contact measurment.

Is this a common mod for the b16a?

Thanks for the information!! I haven't done any measurement, i will do that once when i put the head back. I do worry about the pistons stick out too much. I can not get a definite answer about the CTR piston in B16A clearance, but i do notice everyone is doing it without much problem. I will have the car dyno tune so i shall be ok with that high CR.

ek4 hatchback

Active Member

- Joined

- Oct 28, 2008

- Messages

- 357

i also have a b16 with CTR pistons. i ran them with stock ECU (P2T) for several months and had no problems. but i do recommend a tune.

its running quite nice for the fourth year now

cheers

Thanks for letting me about a P2T ECU would work too. I plan to us a Apex's Power FC.

nice work! good luck with the rest of the build

Thanks.

Sorry guys, my project is going very slow. But i shall be able to drive it before the end of this month.

Here is a picture that i was getting ready to put the engine back in.

Attachments

Last edited:

ek4 hatchback

Active Member

- Joined

- Oct 28, 2008

- Messages

- 357

The compression height on the CTR pistons is 0.73mm more than b16a, which will put it around 0.2mm higher than the b16a block (You could measure this with a DTI to get accurate figure). Ideally you need 1mm piston to head clearance. 3 layer gasket is approx 0.7mm, so be carefull.Ideally you need to clay the engine, as i think your geting tight on your tolerances! I think your CR with these pistons alone in the b16a will be around the 12:1 mark. I think a critical measurement will be the head face to chamber contact measurment.

Is this a common mod for the b16a?

Kiwi, you are correct about the measurement. I measured the piston sticking out of the block approximately 0.2mm and the stock head gasket is about 0.7mm thick.

I put the head back on the block and carefully install the timing belt making sure all the timing mark line up correctly. I rotated the engine by crank pulley, i didn't heard any piston with contact with valve or the head.

Some update, i am almost complete......

New style LMA - suppose to reduce the tapping sound,

ARC radiator,

Thermo block - reduce the heat transfer from the engine to the intake,

By-pass the coolant to the throttle body,

Installed the cylinder head back on the block,

Mugen 4-2-1 header with 2.5 inch collector,

Mugen DC2 airbox - it actually fitting quite well in a EK,

Power FC - will be dyno tune it,

Greddy A/F gauge - watch the Air/fuel mixture all the time shall not do any harm,

Finally a set of Defi gauge (oil temperature, oil temperature and coolant temperature),

That is for now, i am hoping to fire up the engine this coming week..........so worry..........

Attachments

-

$DSC02890.JPG54.8 KB · Views: 4,199

$DSC02890.JPG54.8 KB · Views: 4,199 -

$DSC02906.JPG147.6 KB · Views: 4,058

$DSC02906.JPG147.6 KB · Views: 4,058 -

$DSC02912.JPG75.7 KB · Views: 4,059

$DSC02912.JPG75.7 KB · Views: 4,059 -

$DSC02919.JPG107.3 KB · Views: 4,101

$DSC02919.JPG107.3 KB · Views: 4,101 -

$DSC02939.JPG107.5 KB · Views: 4,208

$DSC02939.JPG107.5 KB · Views: 4,208 -

$DSC02942.JPG142 KB · Views: 4,636

$DSC02942.JPG142 KB · Views: 4,636 -

$DSC02961.JPG81.4 KB · Views: 4,453

$DSC02961.JPG81.4 KB · Views: 4,453 -

$DSC02962.JPG77.6 KB · Views: 4,103

$DSC02962.JPG77.6 KB · Views: 4,103 -

$DSC02948.JPG72.5 KB · Views: 3,943

$DSC02948.JPG72.5 KB · Views: 3,943 -

$DSC02921.JPG84.4 KB · Views: 3,986

$DSC02921.JPG84.4 KB · Views: 3,986

EK9monster

EK9Monster

- Joined

- May 24, 2009

- Messages

- 29

When can have a ride ?!!

Last edited:

forestfighter

ZR-TEC RALLY TEAM

- Joined

- Jun 13, 2008

- Messages

- 315

Great thread - gave me some inspiration!

aaroniverson7

EK9 in progress

- Joined

- May 13, 2010

- Messages

- 8

looking real nice!

gave me some ideas as im looking into building a B18C1.

all the best for the rest of the project.

gave me some ideas as im looking into building a B18C1.

all the best for the rest of the project.

ek4 hatchback

Active Member

- Joined

- Oct 28, 2008

- Messages

- 357

Thanks guy!!

I have started the engine and everything run fine. I took it out for a spin and the engine running very smooth. Took it up into VTEC once (6.5K), it sounded quite healthy.

I will need to change the engine oil before going to the dyno. Probably will get it tune on dyno in October or November.

As for the LMA, it is the new style LMA which Honda replaced the old style. It reduced the taping noise.

I have started the engine and everything run fine. I took it out for a spin and the engine running very smooth. Took it up into VTEC once (6.5K), it sounded quite healthy.

I will need to change the engine oil before going to the dyno. Probably will get it tune on dyno in October or November.

As for the LMA, it is the new style LMA which Honda replaced the old style. It reduced the taping noise.

Lord god, you are my idol!

can you post pictures of all the tools you use with this build?

i lack alot of tools, especially those measuring tools which cost alot here in the Philippines.

dude, seriously you had no back experience in rebuilding an engine before this?

kudos bro. kudos.

can you post pictures of all the tools you use with this build?

i lack alot of tools, especially those measuring tools which cost alot here in the Philippines.

dude, seriously you had no back experience in rebuilding an engine before this?

kudos bro. kudos.

Barryl85

Barry L 85

- Joined

- Jan 16, 2007

- Messages

- 1,565

Thanks guy!!

I have started the engine and everything run fine. I took it out for a spin and the engine running very smooth. Took it up into VTEC once (6.5K), it sounded quite healthy.

I will need to change the engine oil before going to the dyno. Probably will get it tune on dyno in October or November.

As for the LMA, it is the new style LMA which Honda replaced the old style. It reduced the taping noise.

Congrats buddy ! Sounds like you have done a great job on your build, looking forward to see what figures your getting.

Keep us posted !

ek4 hatchback

Active Member

- Joined

- Oct 28, 2008

- Messages

- 357

Update Mar 13, 2011

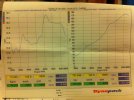

Finally got my car dyno tuned (Apex's Power FC), i am soo happy with the results. All the knocking is gone. I had alot of knocking through the rpm due to the CTR pistons. I shall list my spec. again,

Car: EK4

Engine: B16A

Freshly rebuilt engine with,

- CTR pistons (81.25mm), compression about 12 compression ratio;

- ITR complete cylinder head with cams and valve springs;

- ITR intake manifold with 68mm throttle body + thermoblock gasket;

- Apex's Power FC;

- MDI;

- Mugen DC2 air box;

- Mugen 4-2-1 header;

- EK9 stock cat + stock b-pipe + stock muffler.

After all the tuning, the maximum wheel horsepower 172hp at 8200rpm, limiter set at 8600rpm.

At the dyno,

One final engine photo,

A BIG THANKS to Brian (EK4 SIR) for the tuning on dyno and road tuning afterward.

Finally got my car dyno tuned (Apex's Power FC), i am soo happy with the results. All the knocking is gone. I had alot of knocking through the rpm due to the CTR pistons. I shall list my spec. again,

Car: EK4

Engine: B16A

Freshly rebuilt engine with,

- CTR pistons (81.25mm), compression about 12 compression ratio;

- ITR complete cylinder head with cams and valve springs;

- ITR intake manifold with 68mm throttle body + thermoblock gasket;

- Apex's Power FC;

- MDI;

- Mugen DC2 air box;

- Mugen 4-2-1 header;

- EK9 stock cat + stock b-pipe + stock muffler.

After all the tuning, the maximum wheel horsepower 172hp at 8200rpm, limiter set at 8600rpm.

At the dyno,

One final engine photo,

A BIG THANKS to Brian (EK4 SIR) for the tuning on dyno and road tuning afterward.