ek4 hatchback

Active Member

- Joined

- Oct 28, 2008

- Messages

- 357

Start my long awaited engine rebuild. I am doing the job with hand tools only and working alone. But when i need an extra hand i would call my friend to come and help.

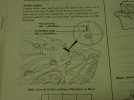

This is the first time i rebuild an engine so i will learn as i work through. I have a Honda service manual on hand and some mechanic friends that i can ask. So i hope i won't screw up anything!!

I work very careful in my fresh painted engine bay (painted last year).

Starting by pull out my EK4 from storage,

Remove the header,

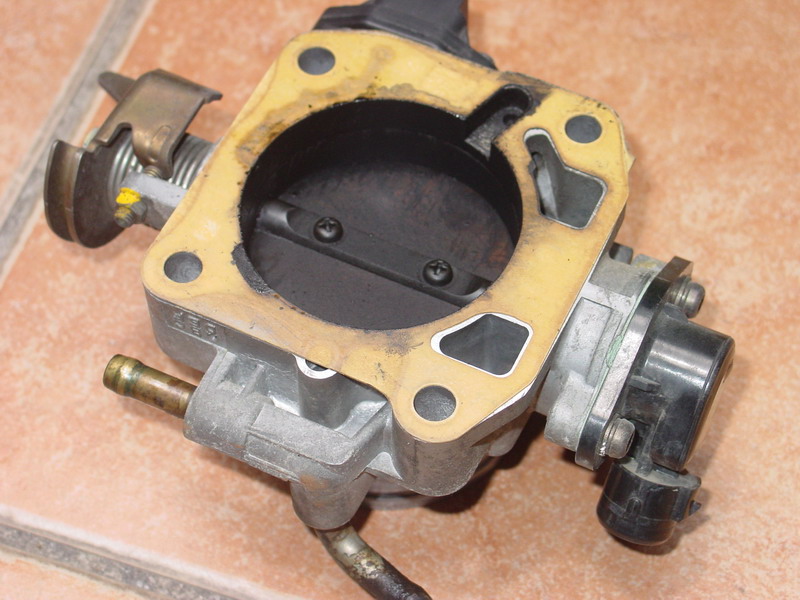

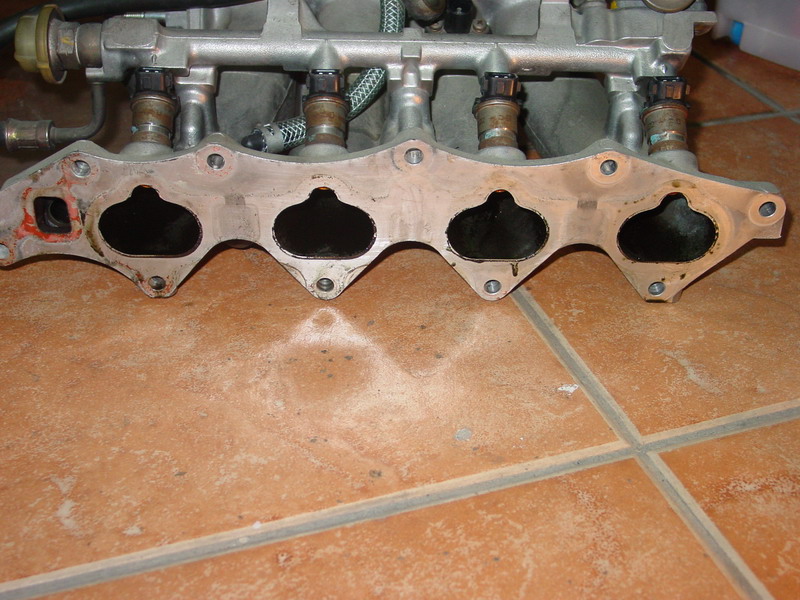

Remove the intake manifold, yes i did remove the monifold from above. It just take some patient and time to remove it. Also be very careful about the fuel line.

The oil built up very badly within the intake, it is due a bad PVC,

Loosen all the suspension bolts include the big axle nut so it get ready to remove the drive axles

Also drain out all the fluid include tranny oil, engine oil and coolant.

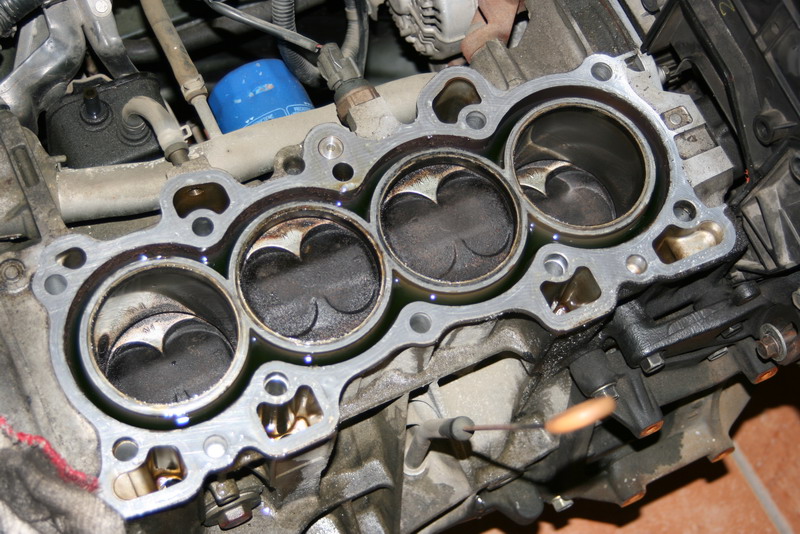

Remove the cylinder head bolts in sequence, the oil built up is very bad in the exhaust side ports

That is for now.....more to come!!

This is the first time i rebuild an engine so i will learn as i work through. I have a Honda service manual on hand and some mechanic friends that i can ask. So i hope i won't screw up anything!!

I work very careful in my fresh painted engine bay (painted last year).

Starting by pull out my EK4 from storage,

Remove the header,

Remove the intake manifold, yes i did remove the monifold from above. It just take some patient and time to remove it. Also be very careful about the fuel line.

The oil built up very badly within the intake, it is due a bad PVC,

Loosen all the suspension bolts include the big axle nut so it get ready to remove the drive axles

Also drain out all the fluid include tranny oil, engine oil and coolant.

Remove the cylinder head bolts in sequence, the oil built up is very bad in the exhaust side ports

That is for now.....more to come!!

Attachments

-

$DSC02698.JPG167.7 KB · Views: 10,604

$DSC02698.JPG167.7 KB · Views: 10,604 -

$DSC02672.JPG111 KB · Views: 10,113

$DSC02672.JPG111 KB · Views: 10,113 -

$DSC02677.JPG132.5 KB · Views: 10,173

$DSC02677.JPG132.5 KB · Views: 10,173 -

$DSC02680.JPG162.9 KB · Views: 10,241

$DSC02680.JPG162.9 KB · Views: 10,241 -

$IMG_8851.JPG86 KB · Views: 9,947

$IMG_8851.JPG86 KB · Views: 9,947 -

$IMG_8864.JPG155.5 KB · Views: 10,746

$IMG_8864.JPG155.5 KB · Views: 10,746 -

$IMG_8884.JPG176.1 KB · Views: 10,682

$IMG_8884.JPG176.1 KB · Views: 10,682 -

$IMG_8890.JPG153 KB · Views: 9,817

$IMG_8890.JPG153 KB · Views: 9,817

Ideally you need to clay the engine, as i think your geting tight on your tolerances! I think your CR with these pistons alone in the b16a will be around the 12:1 mark. I think a critical measurement will be the head face to chamber contact measurment.

Ideally you need to clay the engine, as i think your geting tight on your tolerances! I think your CR with these pistons alone in the b16a will be around the 12:1 mark. I think a critical measurement will be the head face to chamber contact measurment.