HondaNickx

Member

- Joined

- Jan 7, 2010

- Messages

- 166

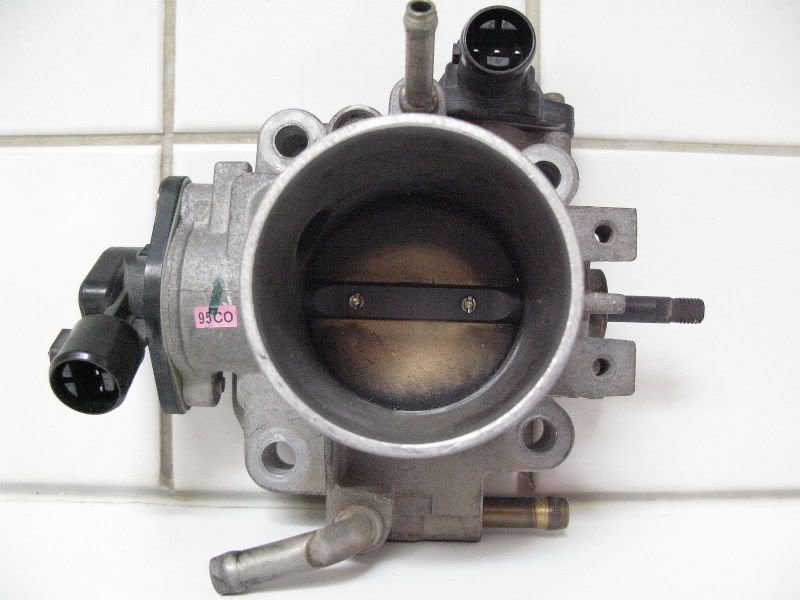

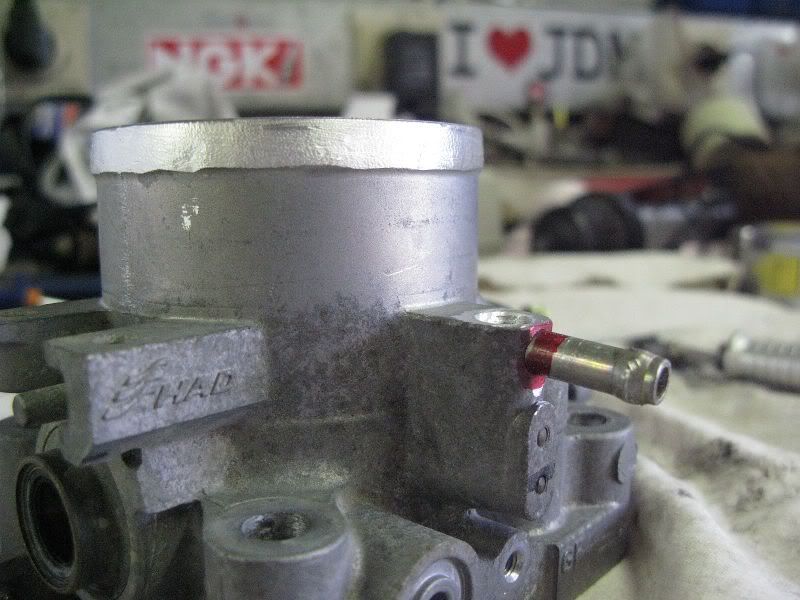

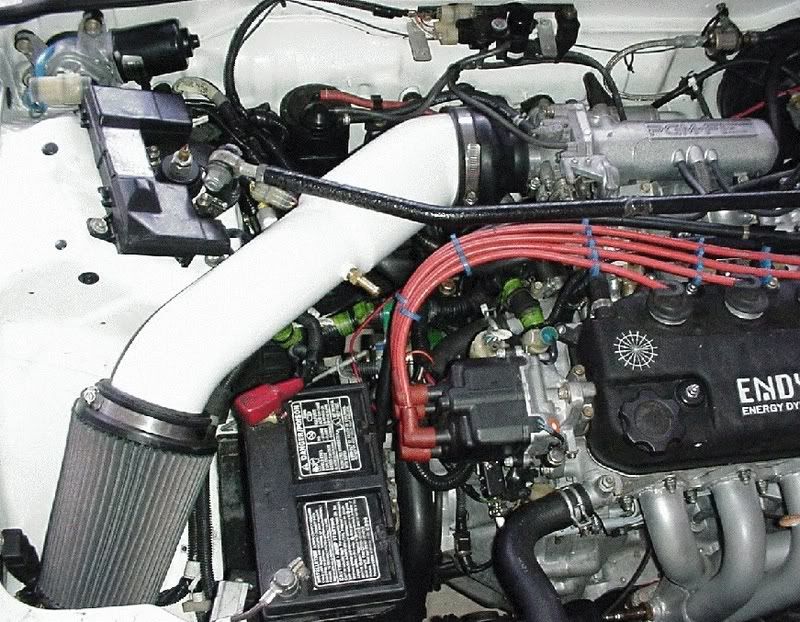

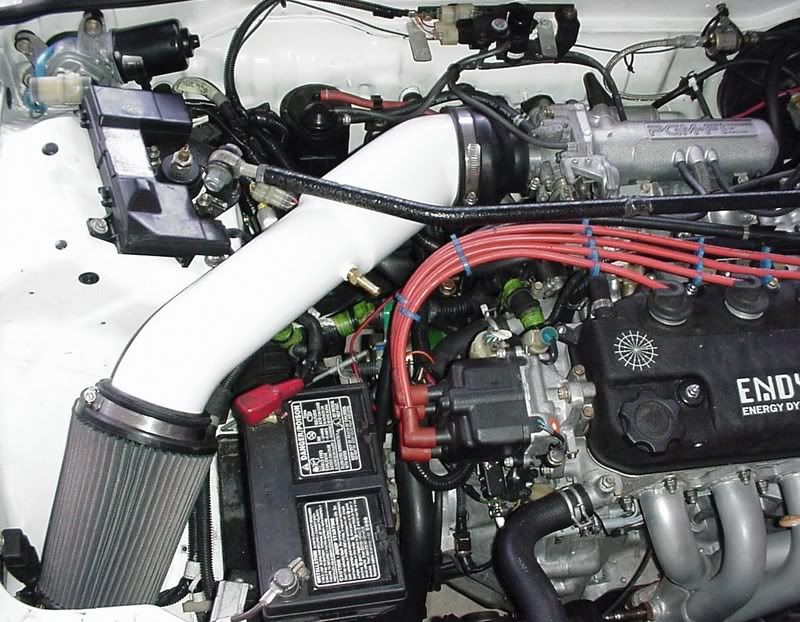

This is something i did a while ago .This topic has lot's of pages on a other forum so i'll just post the most important stuff here  .It applies to a D-series Throttle body but it works on any throttle body that has a butterfly valve.

.It applies to a D-series Throttle body but it works on any throttle body that has a butterfly valve.

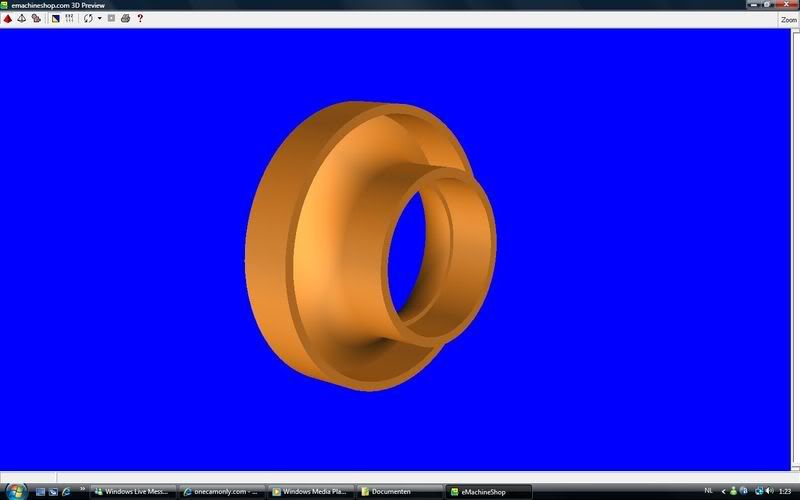

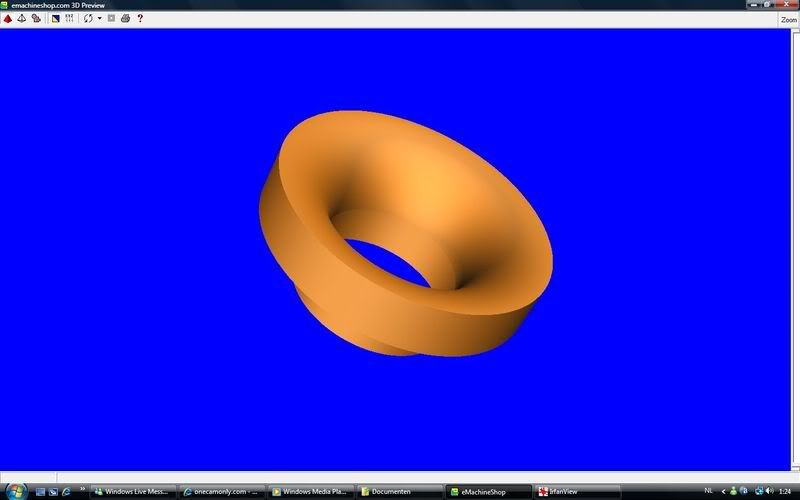

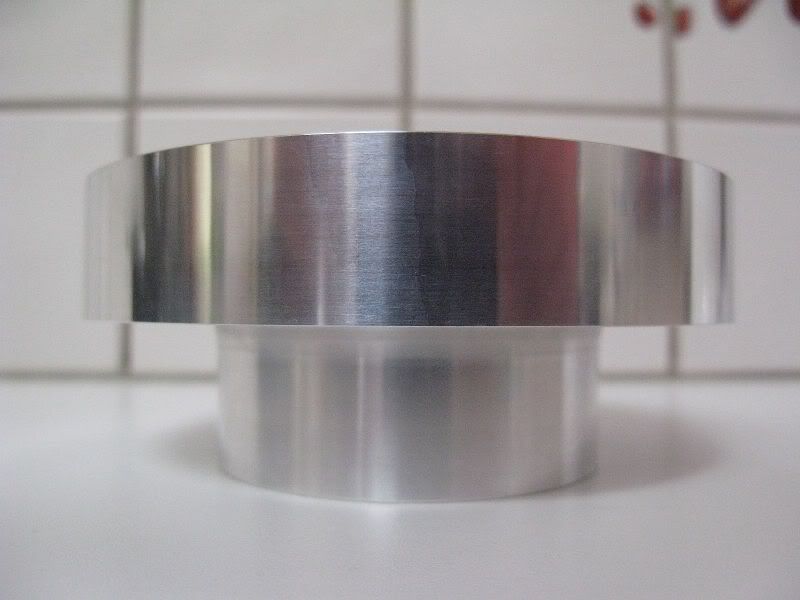

I used Endyn 's archive for the radius and intake calculating and offcourse lots of tips from Rushi for the Tb.Quote from Larry “Using this formula's radius combined with the 25% increase in area in front of the throttle body allows the lower velocity air flow in the inlet "tube" to exert considerable pressure on the throttle body which is highly desirable from a power standpoint.”

I also noticed Larry said to make a Radiused connection wherever possible by using the formula 1/2 of the TB diameter.

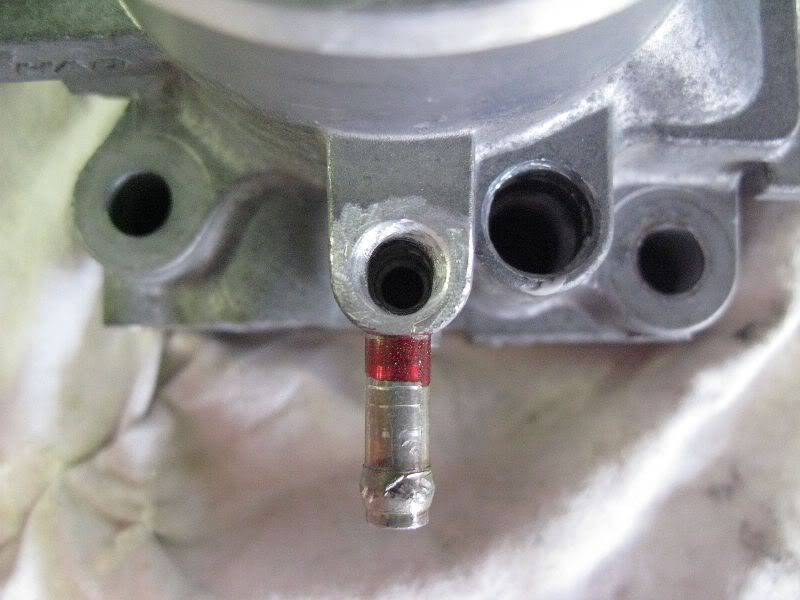

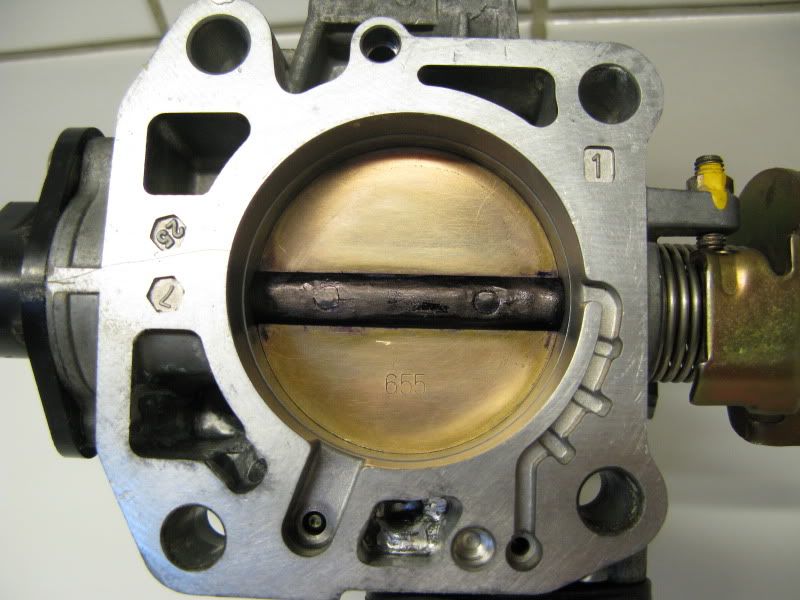

For the throttle shaft i used a method from the book "4 Stroke tuning" from A. Graham Bell.He said there could be gained 10-12% in flow by reducing the shaft thickness ,removing the screws and cutting 1 side away.Other then that i've read on a Skyline forum that some company's used paint for Rc cars to seal the Tb.The trick here was to apply a very thin coating of paint with the butterfly shut.I used Motip white tire marker for this .I had this laying around and i think it will work thesame since it both flexibel paint .I later discovered moly based paint is what they use in OEM TB's.

Note: This was my first design and later i discovered i miscalculated the Radius and actually used half the radius i supposed to use.

I used Endyn 's archive for the radius and intake calculating and offcourse lots of tips from Rushi for the Tb.Quote from Larry “Using this formula's radius combined with the 25% increase in area in front of the throttle body allows the lower velocity air flow in the inlet "tube" to exert considerable pressure on the throttle body which is highly desirable from a power standpoint.”

I also noticed Larry said to make a Radiused connection wherever possible by using the formula 1/2 of the TB diameter.

For the throttle shaft i used a method from the book "4 Stroke tuning" from A. Graham Bell.He said there could be gained 10-12% in flow by reducing the shaft thickness ,removing the screws and cutting 1 side away.Other then that i've read on a Skyline forum that some company's used paint for Rc cars to seal the Tb.The trick here was to apply a very thin coating of paint with the butterfly shut.I used Motip white tire marker for this .I had this laying around and i think it will work thesame since it both flexibel paint .I later discovered moly based paint is what they use in OEM TB's.

Note: This was my first design and later i discovered i miscalculated the Radius and actually used half the radius i supposed to use.

Last edited:

Did it make much difference to power when fitted back on?

Did it make much difference to power when fitted back on? great info

great info