You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High compression turbocharged engines.

- Thread starter Kozy

- Start date

DIY_EK2142

EK Track Car In Prog

- Joined

- Feb 26, 2010

- Messages

- 98

im running 12:1 on 98, but on low boost atm. yet to retune for high boost but going to move up to C16 fuel when i do.

Gorbash12346

Member

- Joined

- May 4, 2009

- Messages

- 580

high pressure direct injection setups can also make high cr boost achievable. would have to redesign the cylinder head to do it though

rs250nut

Boosting since 1998

- Joined

- Feb 14, 2011

- Messages

- 598

So what exactly are the benefits of a high compression boosted motor running on E85, over a regular low compression build running on 99RON?

Are the cylinder pressures not the limiting factor either way?

With a low comp build you have a very lazy motor off boost this can also effect the way the turbo spools. Also with a low comp build you end up running more boost to reverse the lowering of compression ratio, with running more boost you add more problems, with more boost comes higher shaft speeds which wear the turbo quicker, higher boost levels the charge temps go up which then makes the need for a bigger more efficent intercooler etc etc etc. The higher compression route with higher octane fuel to resist knock is a lot more efficent way of doing things. In my eyes fuel is key to any performance engine build, you should decide this way before you buy your first performance part.

- Joined

- Aug 18, 2008

- Messages

- 4,076

I was thinking along those lines, just wasn't sure if the lower energy content of E85 would offset the increases from high compression to the point where it didn't end up making that much difference, only the fuel was a lot more expensive...

Interesting idea though, sounds like all the merits of NA and FI and none of the downsides, fuel cost aside.

Interesting idea though, sounds like all the merits of NA and FI and none of the downsides, fuel cost aside.

With a low comp build you have a very lazy motor off boost this can also effect the way the turbo spools. Also with a low comp build you end up running more boost to reverse the lowering of compression ratio, with running more boost you add more problems, with more boost comes higher shaft speeds which wear the turbo quicker, higher boost levels the charge temps go up which then makes the need for a bigger more efficent intercooler etc etc etc. The higher compression route with higher octane fuel to resist knock is a lot more efficent way of doing things. In my eyes fuel is key to any performance engine build, you should decide this way before you buy your first performance part.

I understand this but it then has me thinking why people have low comp engines at all surely you'd be better of having a standard comp forged engine and running lower boost i just don't see how having high comp is more likely to det than running big boost

rs250nut

Boosting since 1998

- Joined

- Feb 14, 2011

- Messages

- 598

I understand this but it then has me thinking why people have low comp engines at all surely you'd be better of having a standard comp forged engine and running lower boost i just don't see how having high comp is more likely to det than running big boost

I dont know why people bother with low compression turbo set ups, older stuff like r5 gtts and rs turbos etc did this because of poor combustion chamber design (compared with their modern counter parts) which lent them selves to pre ignition and det.

Shift

Member

- Joined

- Oct 6, 2008

- Messages

- 385

My engine before it blew after about 8 years was a totally stock B16B... What the Japs did was put in a thicker head gasket and i was running 10.5 psi daily. Never pulled down or rebuild in any way so I think that it blew from wear and tear over the years. The octane level here in Barbados is about 85....which is horrible. We dont have good gas here.

With proper gas and tune 15-16 psi was safe...but only on race night

With proper gas and tune 15-16 psi was safe...but only on race night

I dont know why people bother with low compression turbo set ups, older stuff like r5 gtts and rs turbos etc did this because of poor combustion chamber design (compared with their modern counter parts) which lent them selves to pre ignition and det.

ah yeah that clears a lot up was thinking of forging my old turbo but didn't really want to loose the pokeyness off boost as i spend 90-95% of the time off boost lol anyway so looks like i shuould be fine with same compression

- Joined

- Aug 18, 2008

- Messages

- 4,076

I dont know why people bother with low compression turbo set ups, older stuff like r5 gtts and rs turbos etc did this because of poor combustion chamber design (compared with their modern counter parts) which lent them selves to pre ignition and det.

Surely it all depends on what power you're aiming for? What you're doing with boost is making the engine bigger, at 1bar boost the engine is effectively double the size it was NA as it is able to inhale twice as much air. If you've got a 400cc cylinder and a 40cc chamber you've got 440cc/40cc = 11:1 compression, with 1bar it would effectively be around 800cc, making it 840cc/40cc = 21:1 CR. That's a shitload of cylinder pressure that I don't think you can mitigate with a bit of extra fuel or retarded timing. My workings suggest over 1000psi prior to ingition, where a standard engine runs around 700-800psi peak.

Going by this, there's obviously going to be a limit to how much boost you can run at a certain CR, which will limit the amount of fuel you can burn which in turn will limit power. If you want more power, you need the boost so you need to drop the CR to make it work without blowing the cylinders wide open. The trade off it poor performance off boost, or building it for E85 which is hard to come by and offers poorer MPG.

rs250nut

Boosting since 1998

- Joined

- Feb 14, 2011

- Messages

- 598

I just typed out a super long reply only for my I phone to crap out anyway, those cars mentioned were low compression from factory, 8.2:1 for the escort and 7.9:1 for the 5. As said before you could research as much a you like ( not saying its a bad thing) but after going round in circles with ve, thermal efficiency, cylinder pressure etc only to end up at the same spot it this time where real life testing comes in to its own. From 1999 to present I have owned 7 r5gtt's all with different setups, as I said above a lot of people with r5's running big boost went low comp,all through trial and error

I ended up with a high comp 2.2 bar motor that made a reliable 230whp that I used as a daily driver.

I ended up with a high comp 2.2 bar motor that made a reliable 230whp that I used as a daily driver.

- Joined

- Aug 18, 2008

- Messages

- 4,076

I ended up with a high comp 2.2 bar motor that made a reliable 230whp that I used as a daily driver.

This sounds interesting...

Is this the R5 engine or a Honda build? 2.2bar guage or absolute? How high is high compression?

If it's on the R5 engine, how did you manage to do that when other were melting pistons on low compression?

You're right, you can't beat experience like that, I would love to hear the thought process behind it though. What made you think to go high compression when the common low compression builds were blowing up left right and center?

TheBooosh...!

Active Member

- Joined

- Nov 17, 2008

- Messages

- 940

Diesel engines are HIGH compression turbo's 20:1 and stuff

Dont rally car's use silly high compression builds?

As for R5's my friend has just upped the boost on his and is going to build a low compression bottom end as he has heard horror stories about the stock engine nto being up to the job!

Dont rally car's use silly high compression builds?

As for R5's my friend has just upped the boost on his and is going to build a low compression bottom end as he has heard horror stories about the stock engine nto being up to the job!

Last edited:

- Joined

- Aug 18, 2008

- Messages

- 4,076

Diesel engines are HIGH compression turbo's 20:1 and stuff

That's how they work though, the pressure is needed to ignite the fuel.

I've been doing some research into engine thermodynamics and I've come up with some plots of what changes when you turbocharge a factory NA engine. Thought I'd post them here with my thoughts on it for discussion. As always, I welcome people telling me if they think I'm wrong.

Anyone who's ever sat a thermodynamics class will be familar with a PV diagram for an otto cycle. If not, some links here and here

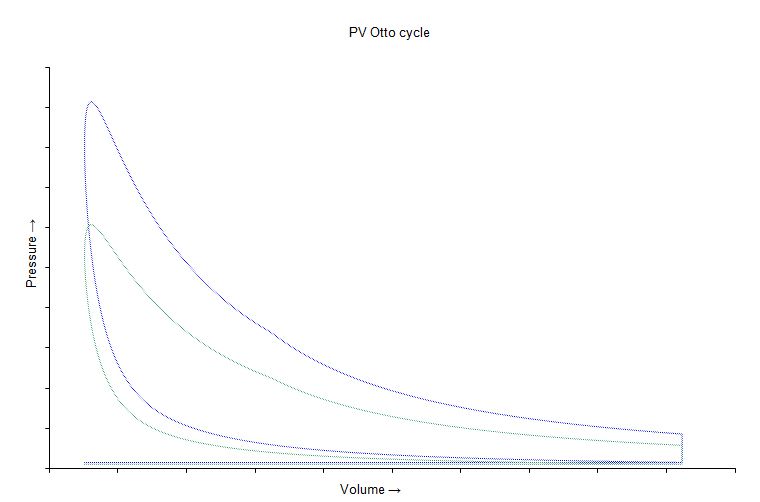

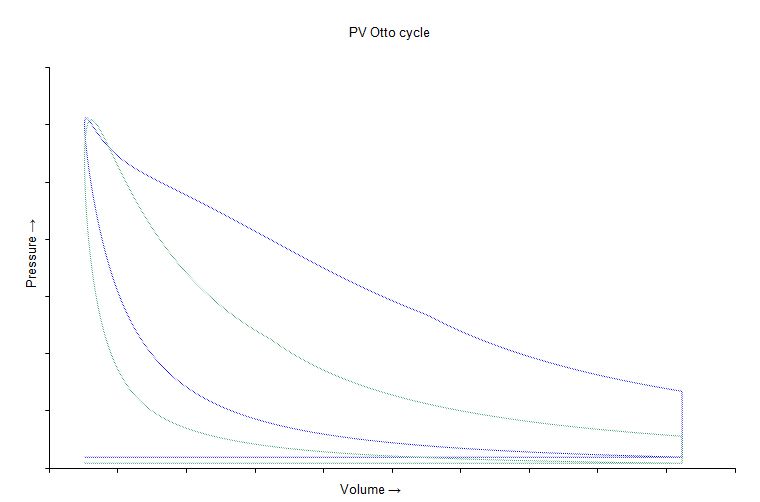

Here's one comparing two engines with B18C geometry, both 11:1 compression, 45° MBT ignition timing, but one force fed 0.5bar to 150% VE. All plots taken at 7200rpm and 13.5AFR.

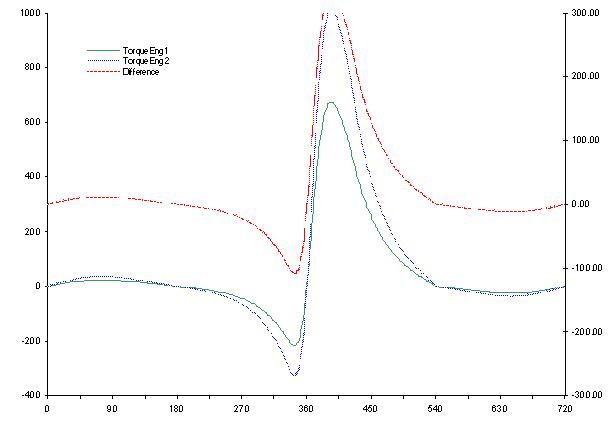

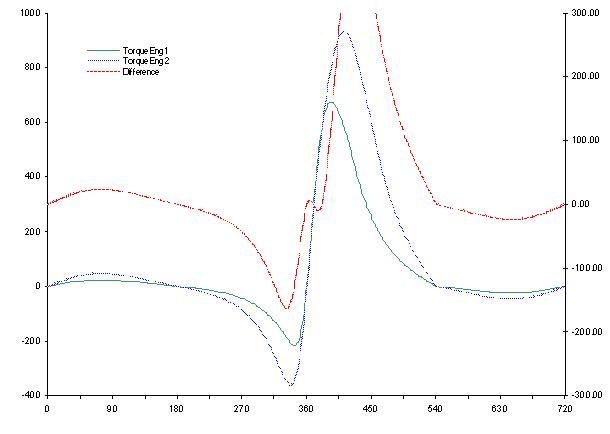

Here is the torque output comparison for one cylinder over one engine cycle.

Clearly the boosted engine is producing a huge amount more cylinder pressure at peak (over 1300psi), which while it makes a huge amount of torque, 234lbft vs 156lbft, it would most likely destroy the engine pretty quckly. The NA engine peaks at just under 900psi, so we'll take this as the safe limit for cylinder pressure.

Below, I've reduced the ignition timing back to 28.5°, the peak cylinder pressure is back at 900psi, but importantly the average pressure has risen from 210psi to 266psi, resulting in 213lbft. This would probably run pretty well.

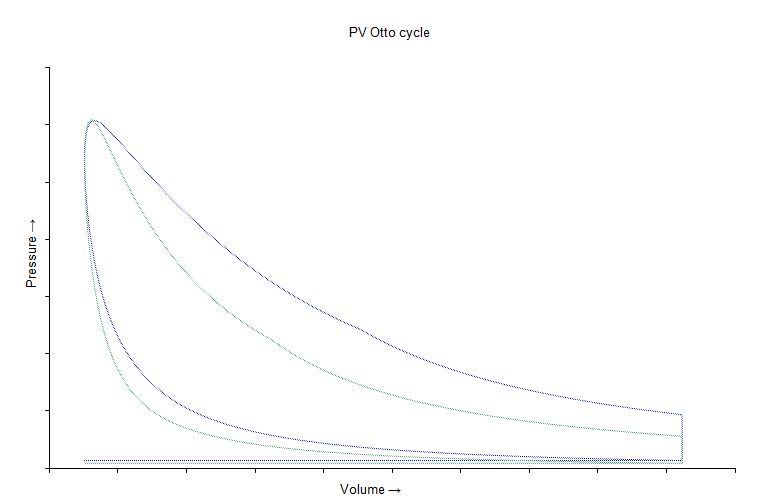

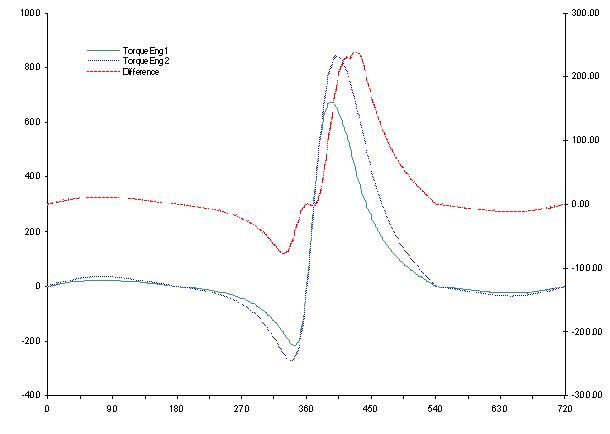

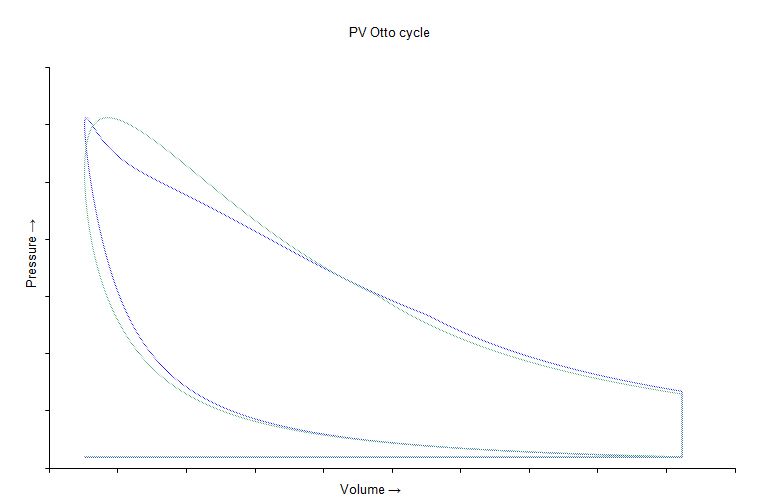

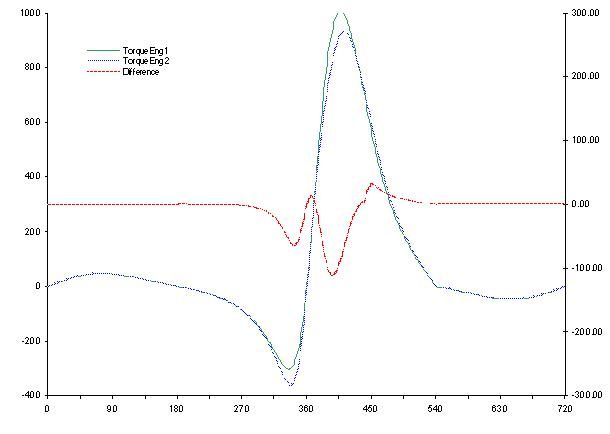

Next, we'll up the boost to 1bar, for 200% VE. This requires the ignition to be dropped back to 16° to keep the peak cylinder pressure under 900psi.

I'd imagine this would not run all that well, but I could be wrong. The hugely retarded timing is obvious just past peak as the pressure drops before the fuel burn really gets going. It makes 244lbft.

Now, lets leave that engine as it is, and take the other one up to 200% VE, but with a 9:1 compression:

Ignition set to 25.4°, torque now at 264lbft. Lots more area visible, and the torque trace shows a gain pretty much everywhere unlike the previous ones which were a drain on torque on the compression stroke. This to me seems a better design for this level of boost.

Food for the discussion...

Last edited:

- Joined

- Aug 18, 2008

- Messages

- 4,076

Food for the discussion...

Or an epic thread kill.

To much for a Civic forum?