Long time without an update here so thought id catch everyone up.

First was a new customer/client had just bought a turbo ep3 and wanted it checked over and the launch control settings played with, so i did that and learnt afew bits about turbo k20s whilst i was there.

Plans for this guy is to run a return fuel line system and then come back so we can turn the boost up. Should see an easy 500 out of this thing!

Then

@B16Swt came round and we tuned his car some more, ill let him update you guys as to how that went when he updates his thread.

Then my brother got a new version of schubandautoworks twinpass intercooler for his car, we still have a pressure drop from compressor to intake somewhere but weve worked around it for now to get him boosting atleast, more from that when we both get time to get out and tune it. Currently peaking at 0.8bar on that on what is really a basemap tbh, wont take us long to have that making proper power!

So the tuning is coming along ok, more cars getting tuned and making power, need to get them on a dyno really though.

Then it was my cars turn,

Bought a larger exhaust housing for it. Its a T31 0.82 A/R with a 3" vband exit welded on. Im hoping this will help it make power at high rpm and high boost instead of the fuel curve dropping off abit after 7500rpm. Visually its much larger than my current 0.63 housing and whilst im there ill replace the current 2.5" downpipe with a 3" version. I should pick up power here simply by less exhaust restriction but itll be interesting to see the effects no less. Im wondering what response is going to be like on the bigger housing, i always thought mine was pretty good but a larger housing should cost me in response alittle bit, perhaps the 3" downpipe will help me get abit of that back. Time will tell...

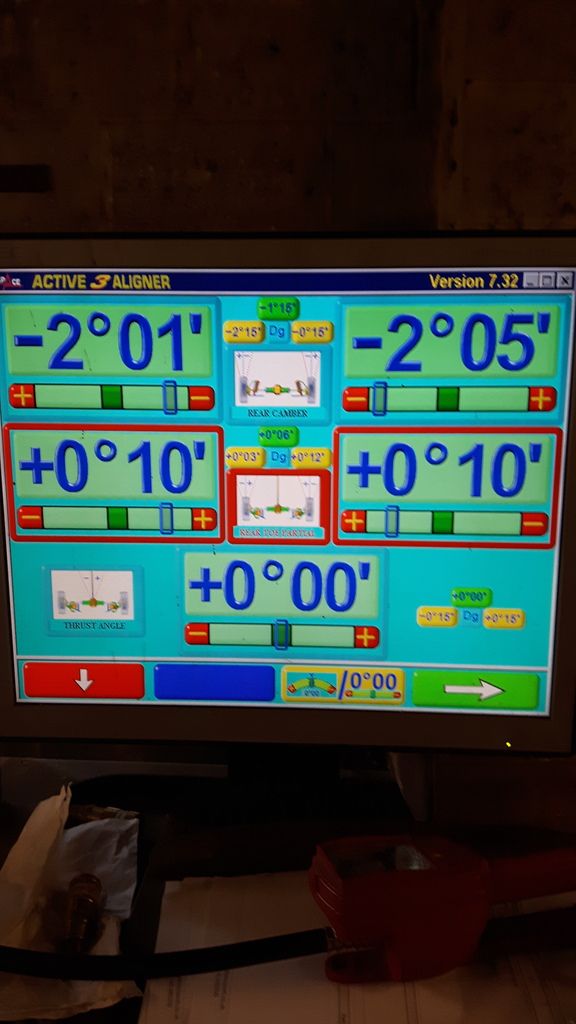

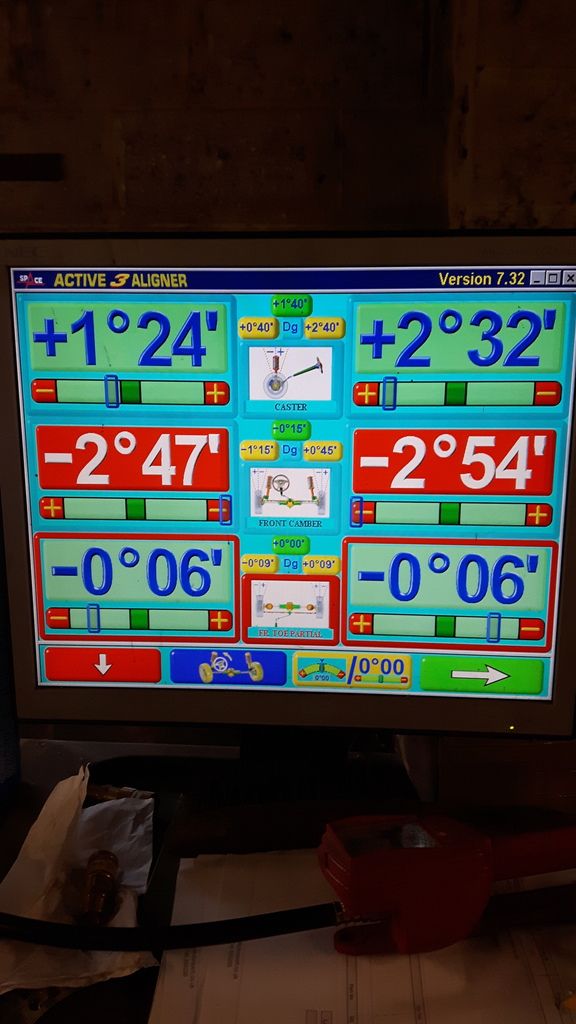

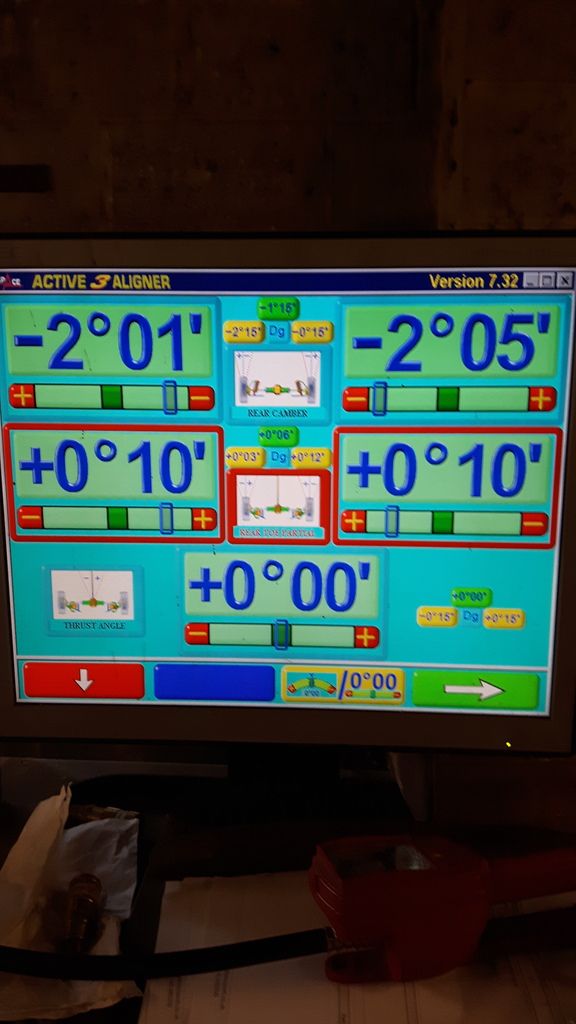

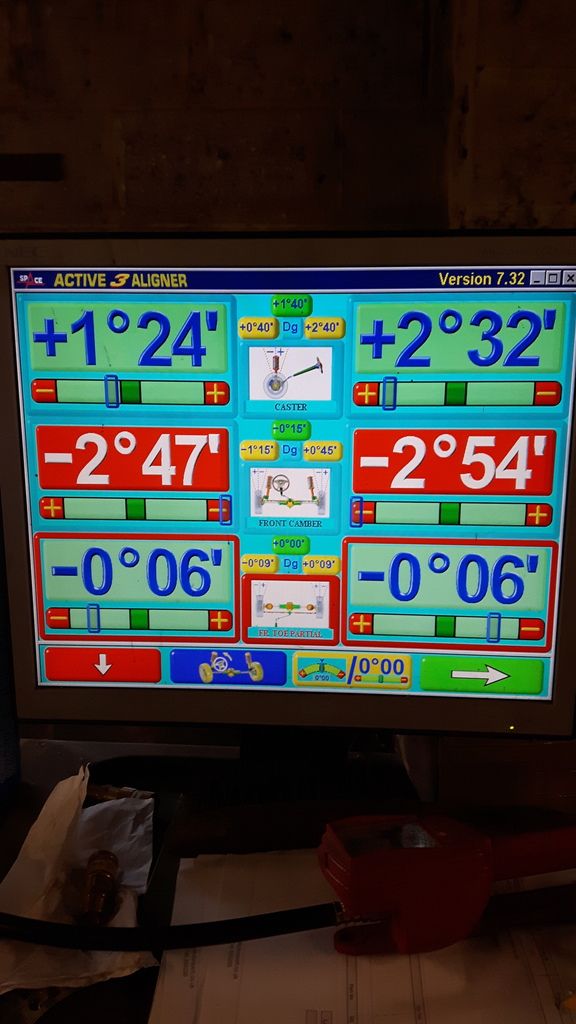

Next it was wheel alignment time! My cars not had a proper geo since before nurburgring 2015(when the camber bolts came loose) ive been Gfabbing it with strings for far too long.

I let the expert do his thing this time and after a short convo he got to the alignment. Ended up with these settings, which arent miles off settings ive had before(never had -3degrees on the front before) he said i need to get him tyre temp data on a trackday so we can further dial it in...

The camber settings even out abit more once im sat in the car but the basics are

Front

-3 camber and 0.06 toe out

Rear

-2camber and 0.10 toe in

The toe in on the rear is me being tight, thats how it ended up after the camber adjustment and its an extra 20 to change it, seen as ill be back with more data anyway i expect this may change again.

Toe out on the front - ive played with this before, the LSD didnt like it at all. I have a plan for it this time though, going to run a new gearbox oil mix and hope that tames the harshness of how the diff locks up. Again time will tell lol

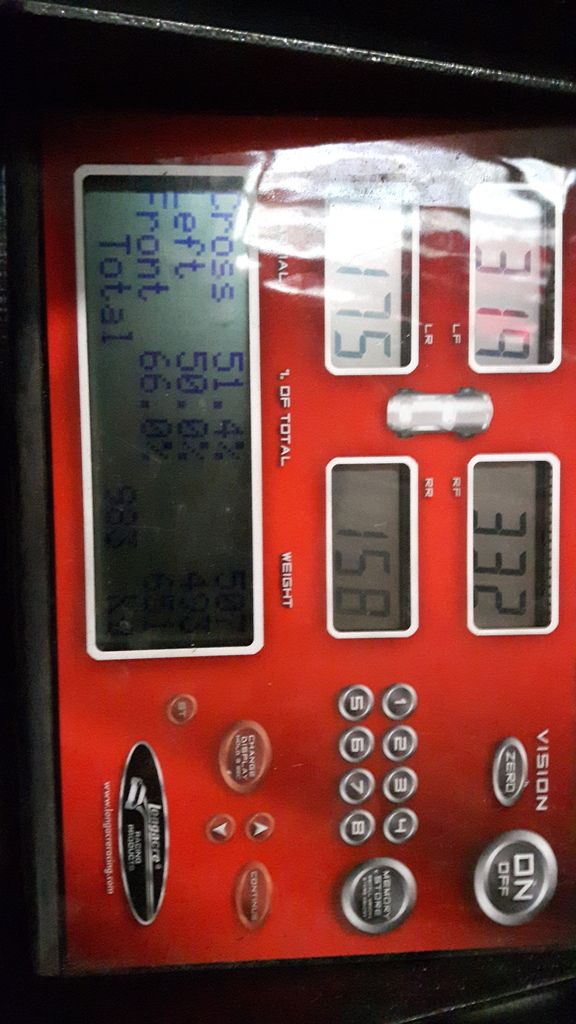

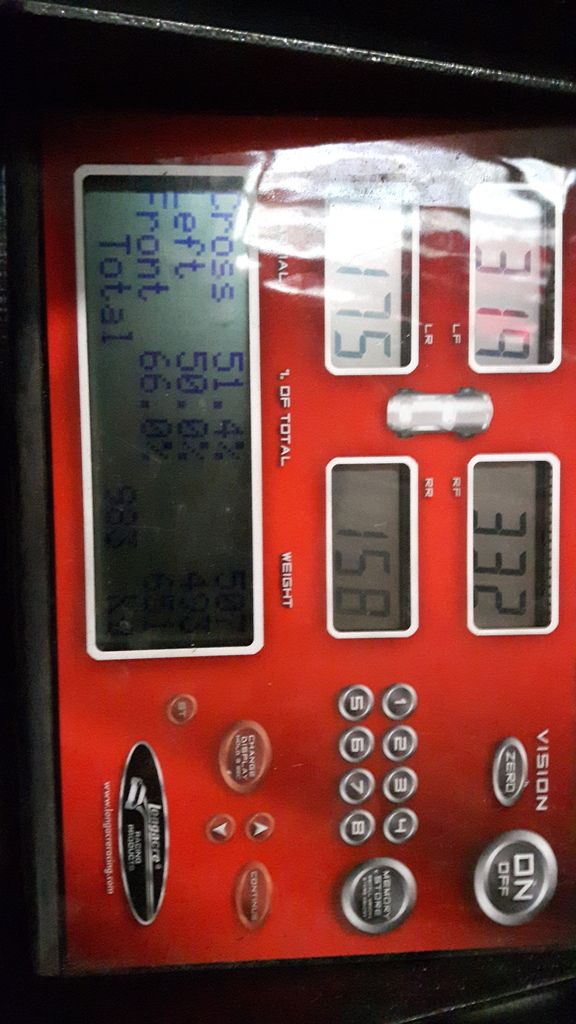

Whilst we was there we got the scales out. Car weighs 983kg without me in it, not too bad. Realistic i guess...

Last but not least, my old sunstrip went when i had the windscreen changed(cracked) so i needed a new on.

I like the large sunstrip look so ended up with this.

And thats us up to date, track evening at brands booked up for the 23rd, full power will be used(weather permitting) so i expect to see a new PB from that.