Sooooo

Found out why the rear end was all over the place at brands last time out.

Wheel bearing lol

So replaced both rear bearings with new items from blueprint.

New brake fluid, gulf RF1000. This is essentially a motul660 equivalent but I didn't fancy the motul, likes be different lol

Also new front and rear pads, opted to stay with the same setup for now. I know how this works and feels so I'll stick with it whilst the engine saga continues.

New dizzy cap, rotor and ignitor aswell, you may have noticed some of my track videos when I come off throttle the Rev needle will drop to zero until I pick up the throttle again. Not sure what this is about but for £42 I can rebuild the whole thing pretty much so hopefully that won't cause issues at the ring!

CL RC6 up front. Love these but they kill wheels and brake discs lol

And finally, not so many pictures because it'll get abit boring keep seeing the same pictures of me having an engine built etc lol

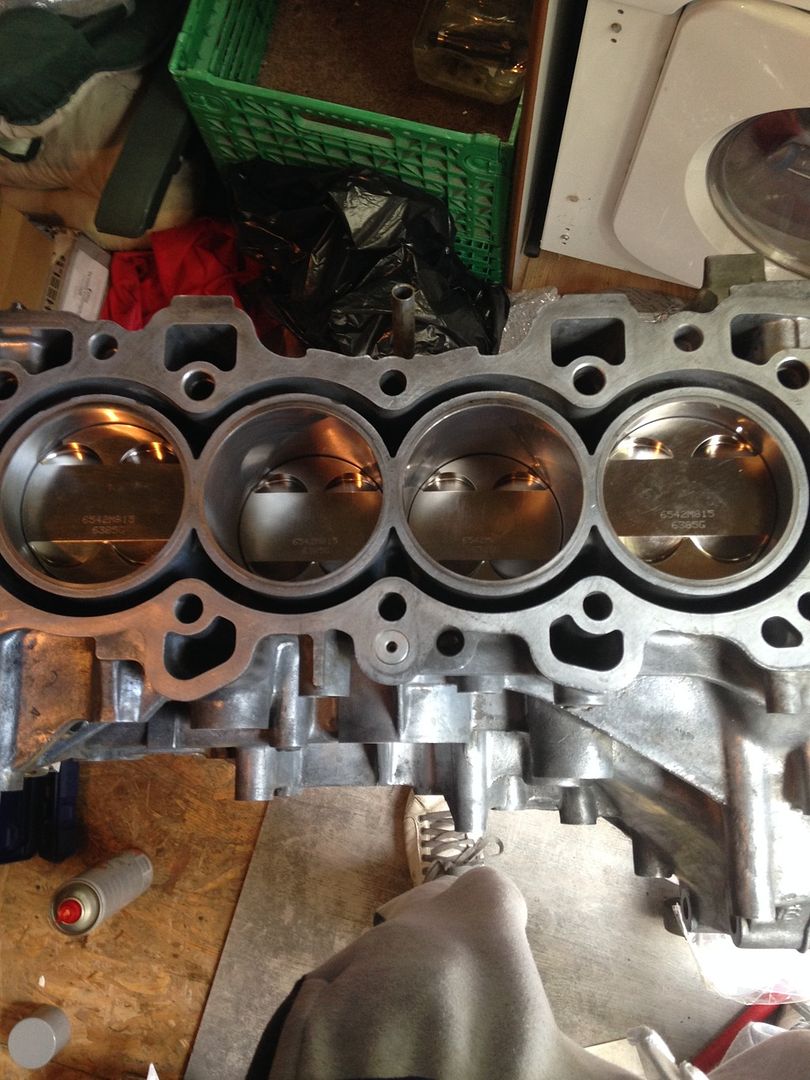

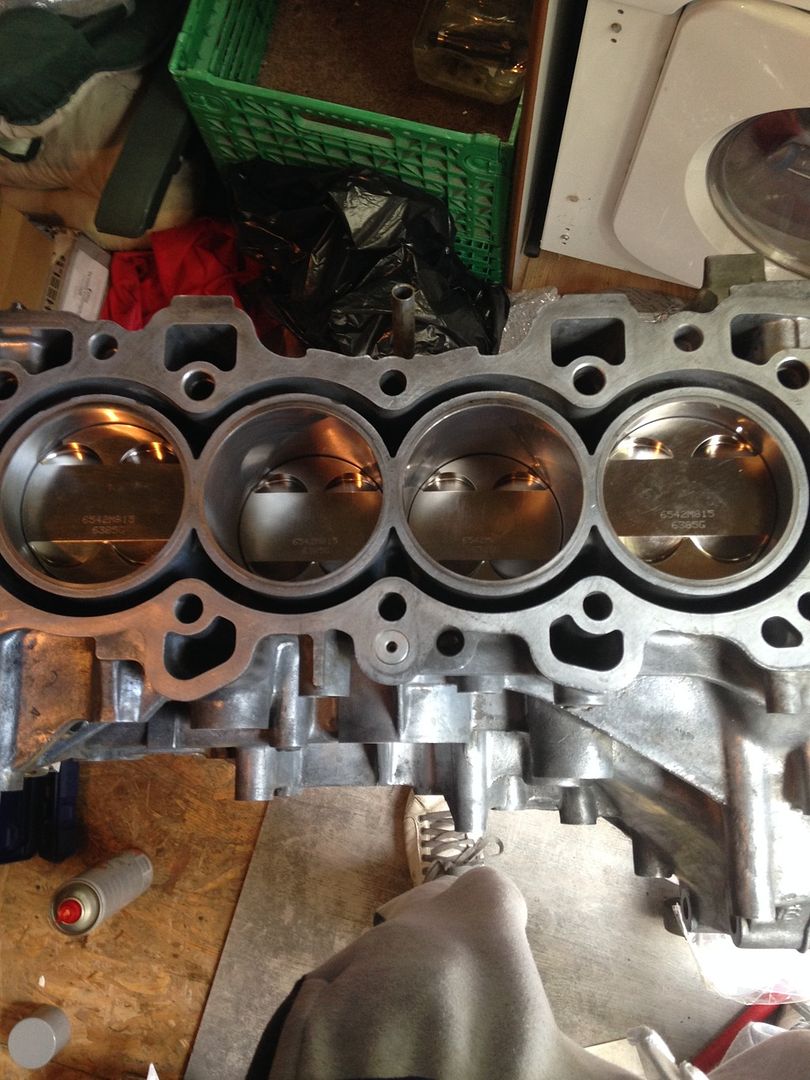

So here's the bottom end complete.

And in the car

So a speedy run down of the new engine

Block honed and cleaned

Crank polished, cleaned and balanced

Flywheel resurfaced/cleaned/balanced

New RPC stage 3 clutch balanced

Distributor rebuilt

Head cleaned up and brake cleaner shot through all galleries

Vtec solenoid stripped/cleaned and reassembled

New Morosso sump

Something I feel worth mentioning, when I took my oil pump out of its packaging(brand new from japservice parts) still sealed in its plastic. I found a lot of what looked like machining dust in the inlet port of the pump. Surely something like this should be spotless straight out the packaging!?!

Needless to say pump was stripped down,cleaned and relubed before going on my new block.

This bottom end is my best effort so far and with the added security of not reusing the old b16b head or either of my coolers I'm hoping/quietly confident that this is the end of this!

I've got till japfest to get the engine running/run in and the whole car prept for the show/track session so I'm a busy bee ATM lol

Hoping to have an "engine is running" update end of the day but anything can happen and get in the way