You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jesse888 Forged/stroker turbo ek9

- Thread starter jesse888

- Start date

- Joined

- Oct 16, 2012

- Messages

- 8,917

Yeah I'm positive enough, I've proved swapping engines isn't much more than 2 days work so if all else fails I'll have a b18c4 in there.

Ironically it's cheaper than rebuilding my forged block everytime(rings,pump,bearings,hone,run in oils and filters etc)

Either way it's coming to and end lol

Ironically it's cheaper than rebuilding my forged block everytime(rings,pump,bearings,hone,run in oils and filters etc)

Either way it's coming to and end lol

- Joined

- Oct 16, 2012

- Messages

- 8,917

Little update.

Been taking this to work all this week. Got around 150miles on it now. I'm off work tomorrow so plan is to get up early and stick another 150ish miles on it in the morning.

Hopefully have close to 1000miles by the time I get the money to rebuild the turbo(suspect bearings)

The compressor wheel feels like it's dragging against something when I turn it with my fingers so it's worth a look I think.

Soon as that's done its book a track evening at brands and see how many laps it lasts lol

I'll be sure to film every stint this time so you guys can see it go.

Been taking this to work all this week. Got around 150miles on it now. I'm off work tomorrow so plan is to get up early and stick another 150ish miles on it in the morning.

Hopefully have close to 1000miles by the time I get the money to rebuild the turbo(suspect bearings)

The compressor wheel feels like it's dragging against something when I turn it with my fingers so it's worth a look I think.

Soon as that's done its book a track evening at brands and see how many laps it lasts lol

I'll be sure to film every stint this time so you guys can see it go.

- Joined

- Oct 16, 2012

- Messages

- 8,917

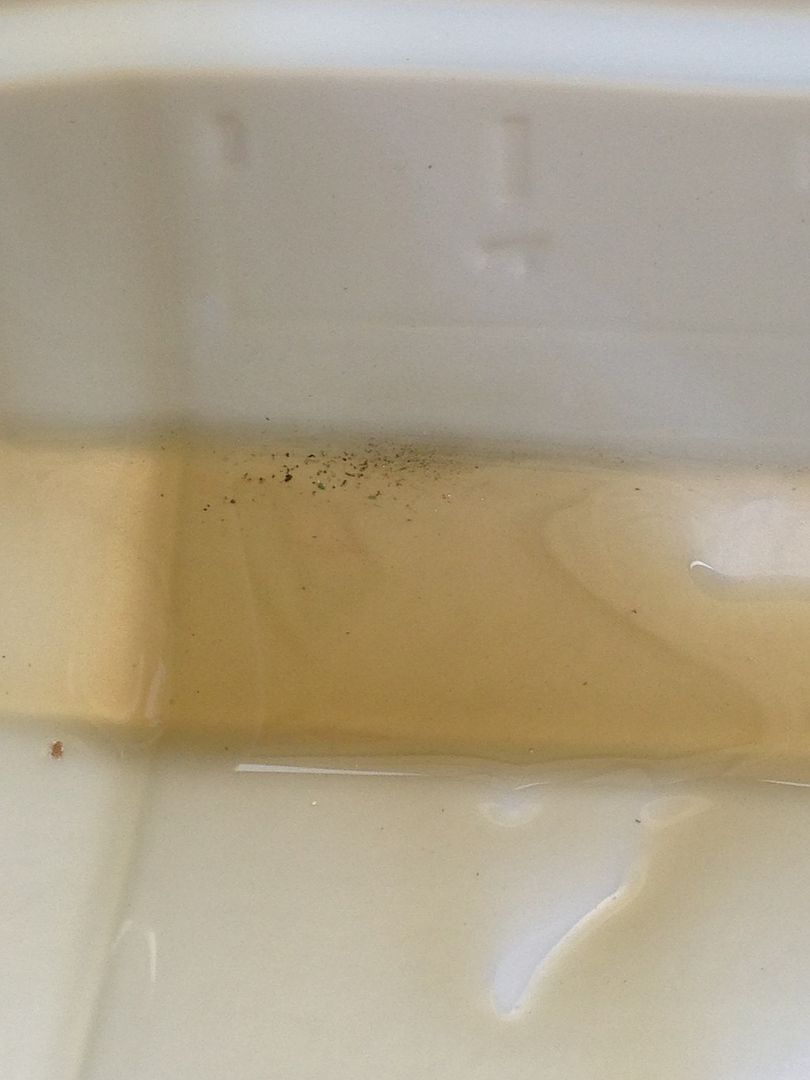

Left the remains of the previous oil change in a clean tub and left the filter upside down aswell.

I wanted to see visually how much metal was being up into the oil, this should allow me to judge how it's progressing. If there's more then it's bad, less obviously good.

I can't find anything online that shows pictures like this just a lot of posts asking if abit of metal is normal in a rebuilt block. Obviously useless to me because how much is too much? If any?

So this is from the first start and 40miles driving

The metal is mostly black with afew silver flakes in.

The next oil change will be around 600miles when I'll put some synthetic in so if there's proportionally more metal in the oil then there's most certainly a problem. If there's same or less then it's heading in the right direction...

Anyone with experience with exactly this please chime in....

I wanted to see visually how much metal was being up into the oil, this should allow me to judge how it's progressing. If there's more then it's bad, less obviously good.

I can't find anything online that shows pictures like this just a lot of posts asking if abit of metal is normal in a rebuilt block. Obviously useless to me because how much is too much? If any?

So this is from the first start and 40miles driving

The metal is mostly black with afew silver flakes in.

The next oil change will be around 600miles when I'll put some synthetic in so if there's proportionally more metal in the oil then there's most certainly a problem. If there's same or less then it's heading in the right direction...

Anyone with experience with exactly this please chime in....

- Joined

- Oct 16, 2012

- Messages

- 8,917

Over 300miles on this now.

Ran fine so far. Should have this batch of oil dropped for some synthetic end of next week so can see how it looks....

I've been tracing coolant leaks for a while and it seems to be getting worse.

It seems to be pushing past the hose clips and seeping out.

I've got a 1.3bar rad cap so maybe it's that pushing past the old hose clips. Think I'm going to replace the leaky ones with jubilee clips and see how it goes then.

If it's not the clips then perhaps it's over pressurising some how.

No overflow into the expansion chamber so I'm doubting I've got a headgasket leak....

Found afew spare clips and made sure the hoses where snug, seems to have fixed the coolant leaks.

320miles down.

Ran fine so far. Should have this batch of oil dropped for some synthetic end of next week so can see how it looks....

I've been tracing coolant leaks for a while and it seems to be getting worse.

It seems to be pushing past the hose clips and seeping out.

I've got a 1.3bar rad cap so maybe it's that pushing past the old hose clips. Think I'm going to replace the leaky ones with jubilee clips and see how it goes then.

If it's not the clips then perhaps it's over pressurising some how.

No overflow into the expansion chamber so I'm doubting I've got a headgasket leak....

Found afew spare clips and made sure the hoses where snug, seems to have fixed the coolant leaks.

320miles down.

Last edited:

- Joined

- Oct 16, 2012

- Messages

- 8,917

Yeah It's hard to know what to do tbh, so many different views on it, I've been doing it my own way that I may do alittle thread on one day explaining why I think doing it a certain way is best etc.

Literally just my veiws on the subject, no real evidence to support

Literally just my veiws on the subject, no real evidence to support

LORD WD40

Active Member

- Joined

- Dec 25, 2011

- Messages

- 238

Do a threadYeah It's hard to know what to do tbh, so many different views on it, I've been doing it my own way that I may do alittle thread on one day explaining why I think doing it a certain way is best etc.

Literally just my veiws on the subject, no real evidence to support

- Joined

- Oct 16, 2012

- Messages

- 8,917

over 450miles on it now. Want to change the oil tomorrow as its pissing down ATM! Going to put some synthetic oil in then I can begin to Rev it I think.

Been really tempting to rev it right round but I've resisted with small bursts upto around 6.5krpm with 0.45bar, not keen on seeing 8800rpm at 1bar boost on mineral oil tbh lol

Been tracing gauge issues and I now need a new oil pressure gauge, so will get one of those installed before I hit some serious boost/revs.

Hopefully get my other SPG fitted soon with another 4 point harness so I can show the civic to friends on track.

New gauge as mentioned

Then I want to get the alignment sorted, I haven't had a proper GEO on this car since I bought it and I've had the steering rack apart and all sorts since. Cornerweighting too if budget allows!

Been really tempting to rev it right round but I've resisted with small bursts upto around 6.5krpm with 0.45bar, not keen on seeing 8800rpm at 1bar boost on mineral oil tbh lol

Been tracing gauge issues and I now need a new oil pressure gauge, so will get one of those installed before I hit some serious boost/revs.

Hopefully get my other SPG fitted soon with another 4 point harness so I can show the civic to friends on track.

New gauge as mentioned

Then I want to get the alignment sorted, I haven't had a proper GEO on this car since I bought it and I've had the steering rack apart and all sorts since. Cornerweighting too if budget allows!

- Joined

- Oct 16, 2012

- Messages

- 8,917

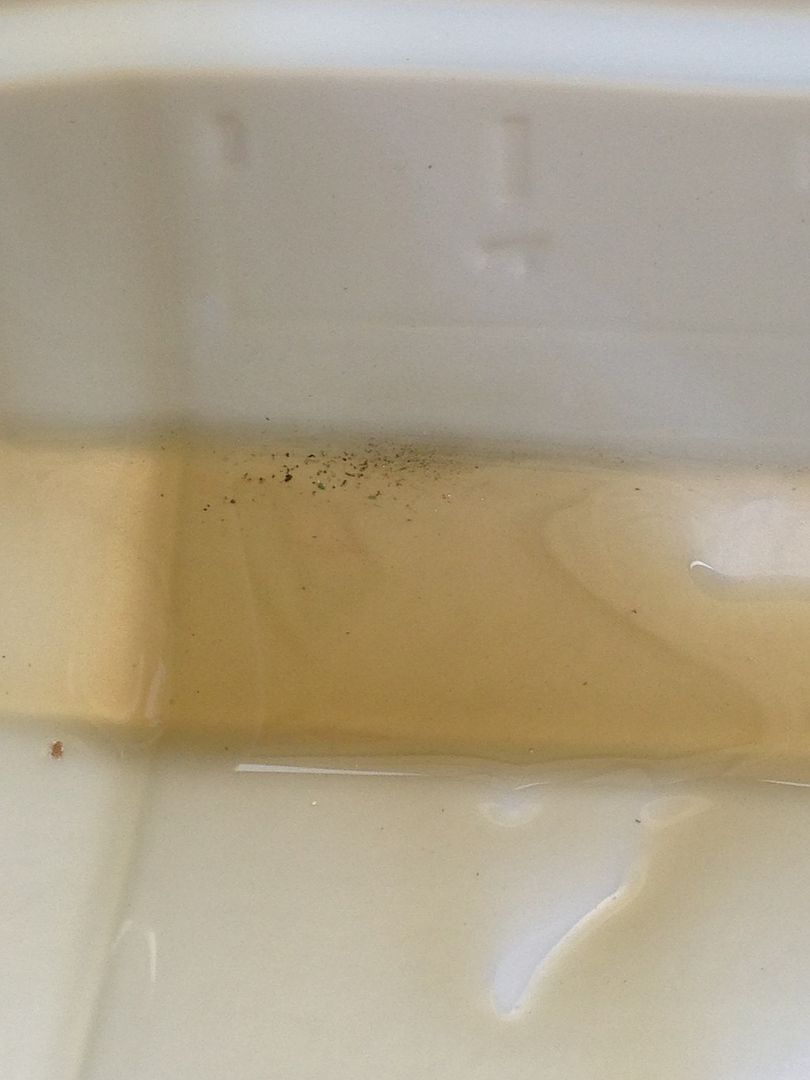

Next pic will probably be another crankshaft.

Same silver metal on the sump plug....

Must be the crank.

I'm hoping to get away with just throwing the crank in with new mains and main cap bolts. New oil pump and start her up. Won't need to run it in again then so should find out very quickly if that's fixed it or not.

Obviously finding a b18c crankshaft is the first hurdle.

Same silver metal on the sump plug....

Must be the crank.

I'm hoping to get away with just throwing the crank in with new mains and main cap bolts. New oil pump and start her up. Won't need to run it in again then so should find out very quickly if that's fixed it or not.

Obviously finding a b18c crankshaft is the first hurdle.

- Joined

- Oct 16, 2012

- Messages

- 8,917

I'm thinking a known good one mate.

Not sure what else it could be tbh.

I can't quite remember fully but the bearings in main cap closest to the oil pump seemed alittle worn compared to the others when I removed them. Stupidly I didn't picture them and just went straight to sorting it out.

Perhaps this proves my bent crank theory after all and I was too blind to even think about it? I should find out with the new bearings when I take the crankshaft back out....Or I'm making stuff up in my mind now lol

Imbalance? The Pistons and rods all weighed the same within 0.5grams and with the fluidampr you'd expect it to atleast slow the wear down, it's exactly the same as it was before so I'm doubting that.

Perhaps the cranks got too much wear on the thrust faces and it's moving in and out too much, kissing the housing of the oil pump?

Cam caps out of alignment? You wouldn't have thought so with how well the b16b crank ran inside it but back to my bearing story above i suppose it's possible?

Main cap bolts over stretched from being reused? I'll replace them with the new crankshaft to rule that out but I doubt it tbh.

Trying to find all possible avenues to explore as I've only got 15weeks till I leave for Germany.

I do feel the crankshaft or atleast the bottom half of the bottom end(if that makes sense?) is too blame, be it the crank, the bearing caps alignment or the bolts I don't know.

This engine is basically trial and error now tbh.

Been to two machine shops, one I don't trust and the other was telling me the last failure was due to dirt ingress, clearly wasn't.....

Not sure what else it could be tbh.

I can't quite remember fully but the bearings in main cap closest to the oil pump seemed alittle worn compared to the others when I removed them. Stupidly I didn't picture them and just went straight to sorting it out.

Perhaps this proves my bent crank theory after all and I was too blind to even think about it? I should find out with the new bearings when I take the crankshaft back out....Or I'm making stuff up in my mind now lol

Imbalance? The Pistons and rods all weighed the same within 0.5grams and with the fluidampr you'd expect it to atleast slow the wear down, it's exactly the same as it was before so I'm doubting that.

Perhaps the cranks got too much wear on the thrust faces and it's moving in and out too much, kissing the housing of the oil pump?

Cam caps out of alignment? You wouldn't have thought so with how well the b16b crank ran inside it but back to my bearing story above i suppose it's possible?

Main cap bolts over stretched from being reused? I'll replace them with the new crankshaft to rule that out but I doubt it tbh.

Trying to find all possible avenues to explore as I've only got 15weeks till I leave for Germany.

I do feel the crankshaft or atleast the bottom half of the bottom end(if that makes sense?) is too blame, be it the crank, the bearing caps alignment or the bolts I don't know.

This engine is basically trial and error now tbh.

Been to two machine shops, one I don't trust and the other was telling me the last failure was due to dirt ingress, clearly wasn't.....

Last edited: