ramboteamjon

Well-Known Member

- Joined

- Apr 21, 2008

- Messages

- 3,010

Yea best being patient mate, great things come to those who wait!

I love christmas too, cant wait!!!!!

I love christmas too, cant wait!!!!!

Don't worry mate i willYea best being patient mate, great things come to those who wait!

I love christmas too, cant wait!!!!!

).gif)

awesome build mate this is the first time i have looked in this thread. Nice to see you doing all the work yourself should be a great engine

Ha,ha,ha thats how it is... Don't forget to let me know before you order.Niceeee

can't wait to get my bits through, im getting excited looking at your parts lol

Excuse me Steven, can you stop drooling over my parts please, thats my job... Thank youdrooooooool

Some nice parts there young Rich, coming together all good!hope you have been thinking about my essay! lol

hmmmm, thank youhmm Nice spec

Very nice mate.

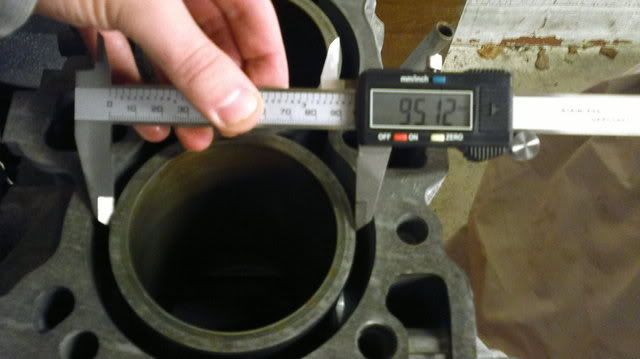

Murrays right man , the max deviation from your preload ''0'' or max range on the dial gauge is the total runout

Thanks for confirming that

Actually, i have a old engine blueprinting book in front of me and it says divide by 2. "Run out = TIR ÷ 2" TIR = Total indicator reading... I'm confused.com... O well, i'm within spec either way lol